Derived lumber products can be used as an alternative for cladding the walls and lids of boxes. Plywood or OSB (Oriented Strand Board) are suitable for building boxes. OSB is a derived lumber product in which long wood strands are arranged in layers, with the strands in each layer oriented at right angles to the next layer and pressed together. For packaging, OSB that is resistant to high humidity is used. This material is known as OSB 3 or OSB 4 and is described in DIN EN 300. These lumber-derived products are used in sheets and have the advantage that they have a very high shearing modulus, which means that diagonal bracing in the walls is not required. The fact that the walls of the box have no gaps also offers protection against spray. When sheet material is used, special care must be taken to ensure that a sufficiently dimensioned interior frame is provided that fulfills the load-bearing function. Furthermore, sheet materials have a lower resistance to knocking and puncturing compared with cut lumber cladding. This applies in particular to OSB as a result of the lower elasticity. The resistance to weathering of plywood and OSB has been proven and is given if plywoods with moisture-resistant glues or OSB 3 or OSB 4 are used. Unlike cut lumber, no phytosanitary requirements apply with these materials, as they are manufactured under pressure and high temperatures. 5.2.1 Requirements with respect to derived lumber products

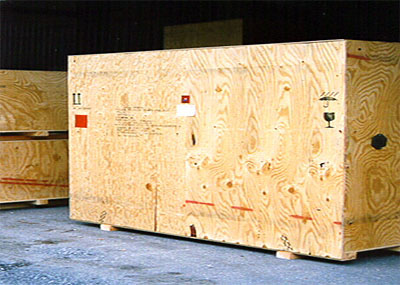

Figures 33a and b: Packaging from lumber derived products (top: OSB, bottom: plywood) The OSB box is also covered with a PE film. This measure is intended for when the box |

| Top of pageContents |