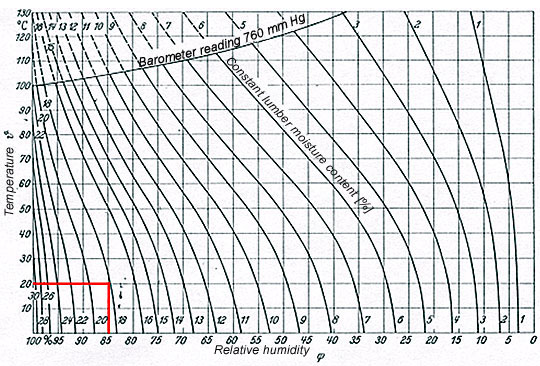

One key property of lumber as a packaging material is its hygroscopicity. Depending on the ambient relative humidity and temperature, lumber absorbs water or releases it to its surroundings until an equilibrium is achieved between the moisture content of the material and the relative humidity of the atmosphere. Lumber intended for the construction of boxes should have a moisture content of 15 % through 18 %, as this moisture content is in equilibrium with the commonly occurring relative humidity levels in Central Europe. The following chart (Figure 30) shows the dependency of the equilibrium moisture content of pine wood on the temperature and relative humidity. In the example marked in red in the chart (Figure 30), lumber with a moisture content of 18 % is in equilibrium at a temperature of 20° C and a relative humidity of 85 %. This climatic data is important with respect to the storage of lumber used for packaging.

Figure 30: Sorption isotherms for pine wood (source: TCI) Excessively moist lumber within packages may, for example, cause corrosion or moisture damage to packaged goods. The extraction resistance of nails and screws also falls as the lumber moisture content rises. See also section 5.5. 5.1.1 Dimensional changes Both excessively moist and excessively dry processed box lumber may have a negative impact on the quality of wooden packaging due to dimensional changes. If the lumber is too moist, gaps appear between the individual boards which had originally been exactly fitted as the lumber shrinks when it dries out. Shrinkage is greatest across the width and depth of the boards. If the lumber is excessively dry during processing, subsequent absorption of water and the resultant swelling may cause boards to lever each other apart, so destabilizing nailed, screwed and bolted joints and impairing the overall strength of the box or crate. 5.1.2 Specific weight The specific weight of lumber is highly variable, and is largely determined by the species of wood and lumber moisture content. The average specific weight of woods used in packaging (spruce, pine) may be assumed to be approx. 450 – 550 kg/m³, while hardwoods (beech, oak) have a specific weight of approx. 650 – 750 kg/m³. 5.1.3 Strength of cut lumber The strength of the lumber varies depending on the type of load (tensile or compressive) across the grain or along the grain. In cross-sections which are free of faults, this variation may be up to 95 %. In addition, the direction of the grain, the number of knots and the moisture content of the lumber also have a considerable impact. Any strength value used for static calculations must therefore incorporate a margin for error. The calculation methods are specified in DIN 1052. The strength of moist lumber is lower than that of dry lumber. In comparison with lumber with a moisture content of 15 %, lumber with a moisture content of 25 % has only half the compressive strength and only approx. 2/3 the flexural strength. 5.1.4 Lumber qualities

Table 10: Quality characteristics for packaging lumber as per DIN 4074 5.1.5 Dimensions Boards and planks are generally unplaned. The following standards apply with respect to the dimensions:

5.1.6 Phytosanitary requirements Many countries have introduced quarantine regulations to protect local forests against imported wood pests. To avoid the evolution of a wide variety of different import regulations, the International Plant Protection Convention (IPPC) issued the ISPM 15 (International Standards for Phytosanitary Measures) "Guidelines for Regulating Wood Packaging Material in International Trade". The ISPM 15 applies to solid wood in thicknesses ≥ 6 mm. ISPM 15 requires the following marking to be applied to two opposite sides of the packaging:

Figure 31: Example of ISPM 15 markings Description of the markings:

Additional information:

Figure 32: Cut lumber packaging |

| Top of pageContents |