There are three main methods used for corrosion protection during shipment of packaged goods:

A further method is also used in the case of closed interior spaces:

When selecting the method to be used, the characteristics of the packaged item and any existing protective measures along with the properties as specified by the manufacturer of the protective agent must be taken into account. It must be remembered that the desiccant method loses its efficacy if the inner packaging is opened and then not re-closed properly by inspectors (customs, etc.) – an unfortunate, but necessary aspect of shipping goods to some countries before they reach their destination. A modern alternative in this context is the active VCI protection method. This method also provides temporary, active corrosion protection in the event that the internal packaging is opened deliberately (goods inspection) or accidentally (damage to the protective cover). 4.4.1 The inert gas method The inert gas method is used to protect closed spaces (containers/pipes) and works by replacing oxygen by nitrogen in the atmosphere. If the inert gas method is used, steps must be taken to ensure that the protective atmosphere cannot escape. This is done by filling the open spaces at a slightly increased pressure and checking this using a manometer. 4.4.2 The protective coating method The protective coating method is a corrosion protection method in which coatings are applied to bare metal surfaces to protect them. For this protection method to be effective, the surface itself must be carefully cleaned and dried.

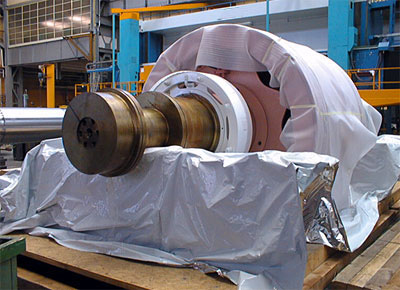

Figure 12: Bare shaft protected by an anti-corrosion coating The protective coating method is a passive corrosion protection method. It can be employed for packaged goods with simple surfaces, which do not present any problems to removal of the protective coating – in general, this is done by washing off the anti-corrosion coating and dissolving it with a solvent.

Figure 13: The way in which solvent-based anticorrosion agents work The coating reduces access for corrosive substances for the planned transport and storage period.

4.4.3 The VCI method (Volatile Corrosion Inhibitor) Unlike the protective coating and desiccant methods, the VCI method offers both active and passive corrosion protection. The chemical corrosion process is actively influenced by vapor phase and contact phase inhibitors. The VCI molecules are deposited on the metal surfaces as a monomolecular layer and inhibit corrosion. No steps are necessary to remove the corrosion protection from the packaged goods. In a simplified form, this method works as follows: Modern VCI products are polar, organic or inorganic compounds providing cathodic or anodic protection. They sublime from the associated carrier materials, saturate the enclosed atmosphere and become deposited (adsorbed) on bare metal surfaces as an invisible, monomolecular film. This process allows them to reach places that are otherwise only accessible with difficulty. Carrier materials can be paper, paperboard, films, foams or emitters, but they can also be included in powders, sprays, oils and water. The VCI atmosphere is established largely independently of ordinary temperatures or humidity levels. A closed protective layer is formed between the metal surface and the ambient atmosphere, thus inhibiting the water molecules in the atmosphere from coming into contact with the metal surface. The mode of action and the requirements dictate how VCI materials are used. Modern VCI products provide multi-metal protection. The monomolecular films on the metal surface neutralize the anodic or cathodic electrochemical processes that lead to corrosion. The metal surfaces of the packaged goods should be as clean as possible to maximize the effect of the VCI method. The VCI carrier material should be no further than 30 cm away from the metal surface to be protected. If the distances involved are greater or if the internal volume is larger (plant equipment), additional VCI carrier materials must be used. It makes sense to seal the packaging space in such a way that the VCI molecules cannot escape from the packaging. It is possible to use or further process the goods immediately they are unpacked, because the molecular VCI protective film volatilizes automatically. VCI products should be free of nitrites, heavy metals, halogens, silicates or other substances that are subject to labeling requirements. The protective effect and compatibility issues must be verified in consultation with the manufacturer. VCI products from different manufacturers are not compatible, because the chemical composition of the products varies. VCI products from one manufacturer only should be used:

Figure 14: The way in which VCI agents work

Figire 15: The closed VCI film VCI applications:

Figure 16: Use of different VCI types. Key to application example: To achieve ideal system conditions, the VCIs used during manufacturing and storage should be the compatible with those used during final protection.

Figure 17: Ideal system conditions as a result of compatible VCI corrosion Summary: Temporary VCI corrosion protection is a key aspect of modern manufacturing, storage and shipping packaging. Universal application coupled with simple handling means that a suitable solution can be found for virtually any task, that has the added advantage that it is easy to use and requires no complex preparations. The majority of VCI products are compatible with the workplace, free of hazardous substances and simply disposed of. The protective function of VCIs has no impact on the electrical, electronic, mechanical or optical properties of the goods that are protected.

Figure 18: Anticorrosion protection by wrapping in VCI film Unlike normal PE film, VCI film is dyed different colors by the various manufacturers. Films are available which only release VCI molecules on one side. This active side is then marked accordingly. 4.4.4 The desiccant method According to DIN 55 473, the purpose of using desiccants is as follows: "desiccants are intended to protect the package contents from excess humidity during transport and storage in order to prevent corrosion, mold growth and the like".

Figure 19: Example: Corrosion behavior of low-alloy steels – qualitative* *Chart as per Verrson The yellow area in the chart indicates the area in which the desiccant method is effective and which starts at less than 40 % RH. An atmosphere is created in which the packaged goods (metals) will not corrode for the specified period over which the protection is to extend. The maximum transport and storage time that can be guaranteed is three years. Mode of action: The air in a water-tight / water vapor-tight film cover is dried with desiccants to a level at which it is not possible for any corrosive processes to occur on the packaged goods during the entire transport and storage time (see Figure 19). The film covers can be very large and are adapted to suit the packaged goods. The cover material is either polyethylene film (PE) or an aluminum/PE composite film. The covers are manufactured by heat-sealing individual film webs. The desiccants used are described together with their properties in DIN 55 473. The necessary quantity of desiccant can be derived on the basis of the dimensions of the cover, the cover material, any hygroscopic accompanying material and the transport and storage time using DIN 55 474. All types of packaged goods can be protected using the desiccant method, and no steps are necessary to remove corrosion protection from the packaged goods. The desiccant bags contain desiccants which absorb water vapor, are insoluble in water and are chemically inert, such as silica gel, aluminum silicate, alumina, blue gel, bentonite, molecular sieves etc. Due to the absorbency of the desiccants, humidity in the atmosphere of the film cover is reduced, so eliminating the risk of corrosion for the duration of transport and storage. Since the absorbency of the desiccants is finite, this method is only possible if the package contents are enclosed in barrier layer which is impermeable to water or water vapor. This is known as a climate-controlled or sealed package. If the barrier layer is not impermeable to water vapor, the difference in water vapor pressure between the interior of the barrier layer (dry) and the external ambient climate (humid) allows water molecules to diffuse inwards through the cover. This is the case with PE film covers. This aspect is taken into account by the water vapor permeability of the cover material when calculating the required quantity of desiccant.

Figure 20: Water vapor diffusion mechanism from the Water vapor always diffuses from a higher humidity level to a lower humidity level. The effect of the difference in pressure can be illustrated with a U-shaped tube. If you open the valve (30 %), the higher level would fall to 60 % and the lower level would rise to 60 %. This would establish an equilibrium. The film covers act in a similar manner. The higher water vapor pressure outside the film cover attempts to balance out the lower water vapor pressure inside the film cover. Desiccants are commercially available in desiccant units. The number of desiccant units is a measure of the adsorption capacity of the desiccant bag. Desiccants are supplied in bags of 8, 16 or 32 desiccant units. They are available in low-dusting and dust-tight forms for the applications discussed here. The latter are used if the package contents have particular requirements in this respect. The number of desiccant units required is calculated as laid down in DIN 55 474. Calculation of the required number (n) of desiccant units: n =

Table 9: Notation used for calculating the number of desiccant units** **Table 9 as per DIN 55 474

Figure 21: Construction of a desiccant system Monitoring of the climatic conditions (temperature/relative humidity) in a closed film cover can be carried out using indicators for the entire storage and transport time, see section 4.5. Figures 22a and 22b show heavy cargo packages with corrosion protection using the desiccant method:

Figure 22a: Aluminum composite film cover

Figure 22b: PE film cover Barrier films for covers are available in various forms, for example as a polyethylene film or as a composite films with two outer polyethylene layers and an aluminum core (aluminum composite films). With respect to water vapor permeability (WVP), aluminum composite film performs far better than PE film. In the former case, WVP values below 0.1 (g/m²d) are achieved (see sample calculation in section 4.4.4). In accordance with current DIN standards, water vapor permeability is always stated for both 20 °C and 40 °C. According to information from the manufacturer, it may be concluded that water vapor permeability rises with increasing temperature and falls with increasing film thickness. This problem arises in particular with polyethylene films. Aluminum composite films, on the other hand, are generally less sensitive to increases in temperature with respect to WVP. If possible, the desiccants should be suspended from two strings in the upper part of the climate-controlled package to ensure good air circulation around them. It is essential to avoid direct contact between the desiccant bag and the package contents as the moist desiccant would promote corrosion. It is advisable to use as many small bags as possible rather than fewer large ones, as this increases the available surface area of the desiccant and so improves absorption of the moisture. In order to ensure the longest possible duration of protection, the barrier film must be sealed immediately once the desiccant bags have been inserted. Desiccant bags are always supplied in certain basic package sizes which, depending upon the number of desiccant units, may contain a single bag (of 32 units) or up to 100 bags (of 1/6 units). The basic outer package should only be opened directly before removal of a bag and must immediately be heat sealed again. The outer package also generally contains an indicator that guarantees that the desiccant is active if it is colored blue. If the desiccant method is used, it is vital that the film cover remains absolutely airtight throughout the entire duration of transport and storage to ensure that the microclimate in the cover is upheld. The desiccant method loses its efficacy if the inner packaging is opened and then not re-closed properly by inspectors (customs, etc.). In the case of technical packaged goods, which are often relatively heavy, it is necessary that the goods are firmly secured to the floor of the box to allow effective load securing. This is generally achieved by bolting. In this case, care must be taken to ensure that all points at which the film cover is punctured must be adequately sealed, for instance using intermediate rubber layers around the bolting points. The same applies to chocks and wedges.

Figure 23: Example of a bolted connection between the Even minimal damage or loss of airtightness of the film considerably reduces the effect of the protective film.

Figure 24: Closed PE film cover with desiccants To check that the film cover is airtight, it is possible to pump out the enclosed air and observe the behavior of the cover. The cover must then be filled with air again in order to ensure that the air can circulate, otherwise the desiccants may not function properly. Because the air is evacuated to check that the cover is airtight, the desiccant method is sometimes referred to incorrectly as the "vacuum method". If boxes using film cover packaging are to be transported in the cargo holds of cargo aircraft, you should note that not all cargo holds in all aircraft are kept at normal pressure. This can cause the film covers to expand. No cases are, however, known in which film covers have burst during transport by air. Valves are available that can be incorporated in film covers that allow excess pressure to escape. Such valves were not specifically designed for the packaging applications discussed here, but it would nevertheless be possible to use them. |

| Top of page | Contents |