4.4

Securing against sliding in the transverse direction by slack tie-down lashing

This example is intended to demonstrate

that a tolerable cargo movement may also reestablish the securing effect of

slackened tie-down lashings in the transverse

direction. The same circumstances as in the preceding example are used for this

purpose.

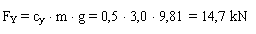

The external force is determined as

conventionally agreed.

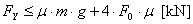

Conventional assessment of the securing against sideways sliding:

According to the conventional assessment,

securing is not adequate, with a shortfall of a good 3%. Here too it is

subsequently assumed that the pretension F0 in the tie-down lashing

has been lost due to the cargo units moving closer together.

Unlike in the

preceding example, where the movement distance selected was the DX value at which the belts still just grip the surface of

the cargo by friction, in this example the movement distance DY to be assumed was to be determined on the basis of the

geometric conditions of the loading area.

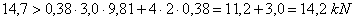

The cargo package has

a breadth of 2.4 m. At an assumed net breadth of the loading area of 2.5 m and

with initially central loading, the pallets may slip by 5 cm to the side before

coming into contact with the sidewalls. Racking (shear deformation) is

additionally assumed, in which the upper edges of the units are pulled a

further 10 cm to the side.

Figure 21: Cargo sliding and racking DY in

Querrichtung

The lengthening of

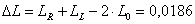

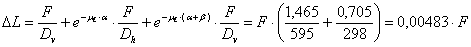

the belts arising from these movements is calculated:

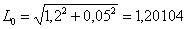

| Initial length of the external parts of the belt: |  m m |

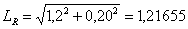

| New length on the right: |  m m |

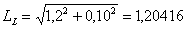

| New length on the left: |  m m |

| Change in length: |  m m |

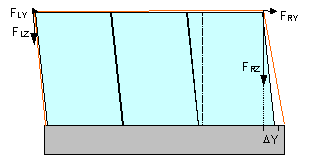

This change in length

results in force being created in the belt, which is distributed such that the

force FR acts in the right-hand vertical part of the belt, while

forces reduced by Euler’s friction losses act in the horizontal central part

and the left-hand vertical part. The individual changes in length must again

correspond to the total change in length. Change of direction on the right

amounts to a = 81° = 1.40 rad, while change of direction on

the left amounts to b = 95° = 1.66 rad. The coefficient of friction mL = 0.25

applies as in the preceding example.

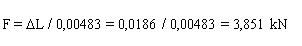

FR = 3,851 kN

with FRY = 0,60 kN and FRZ = 3,80 kN accordingly acts in the right-hand part of the belt

FL

= 0,465 × FR =1,791 kN with FLY = 0,16 kN and FLZ

= 1,78 kN acts in the left-hand part of the belt

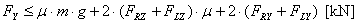

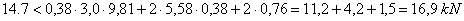

The balance is completed with these values:

The balance is achieved with a surplus of

15%, any possible retention forces arising from the edge of the loading area

having been disregarded. This example confirms that a slight cargo movement can

compensate the complete loss of pretension. However, it must not be concluded

on this basis that pre-tensioning is unimportant. Instead, the actual, more

probable mode of action of a tie-down lashing should be pointed out, which does

not correspond to that represented in the conventional approach to calculation.

The conventional approach to calculation clearly does not adequately model the

physics to be applied in this case.

It is not yet possible to state the

extent to which the conventional approach to calculation may need to be modified on this basis.

|