| Container Transportation – More Than A Coloured Box |

[German version] |

| A lecture from Mr Uwe-Peter Schieder, GDV | |

Table of contents

Watching handling operations in a container terminal from a distance reminds one of piling up building blocks. However, the movements of these colored boxes are anything other than child’s play. They are the heartbeat of our global economic system. They transport the goods, that is to say the assets, generated by the economy.

One problem in this breakneck flow of merchandise often goes unnoticed. When the goods enter the container they become cargo. Even if the container looks like a garage, it is simply a cargo unit which may then be loaded onto a means of transport. However, the different means of transport generate their own stresses which the cargo has to withstand. These stresses are both mechanical and climatic in nature.

Summary

Goods transported in containers are subject to various stresses. Overcoming these stresses demands fit-for-purpose packaging, appropriate load securing and correct humidity management. The goods, in the form of cargo, demand expert handling. Only good training and a commitment to quality can lead to secure, responsible transportation.

Back to beginning

Mechanical stresses during road, rail and maritime transport

The International Maritime Organization (IMO) has recognized the problems caused by mechanical stresses and, some years ago, drew up the internationally acknowledged CTU packing guidelines. These CTU packing guidelines clearly indicate the acceleration forces that can be expected during transportation using the various means of transport. I should like to illustrate these stresses on the basis of a few examples.

In the case of road transport, the value is 1 g in the direction of travel:

Figure 1 [Ridder]

Seventeen tonnes of steel pipes inserted inside one another.

Simply a braking maneuver, i.e. normal acceleration.

(Photo of the month – February 2003)

In the case of maritime transport: At sea, acceleration may occur tens of thousands of times.

Figure 2 [Hapag Lloyd]: Three photos of rough seas

(Photo of the month – January 2004)

The next Figures again shows that a container is not a garage but a cargo unit exposed to different forces.

Figure 3 [Schwarze, Bremerhaven] |

Figure 4 [Schwarze, Bremerhaven] |

In the case of rail transport:

Figure 5

(Photo of the month – February 2002)

This Figure makes it clear that rail transport is also subject to acceleration forces which demand suitably secured loads.

The CTU packing guidelines indicate precise acceleration forces which the cargo has to be secured against. Any national regulations take precedence over the CTU guidelines, in particular in the case of land transport.

Figure 6

Table from the German CTU packing guidelines

Figure 7

Acceleration values from the German CTU packing guidelines

Just two examples from maritime and road transport:

In the case of road transport, the cargo must be secured at 1 g in the direction of travel. This means that the cargo must be secured to counteract its own weight force. If the pipes displayed earlier had been secured in this way, nothing would have happened.

In the case of international maritime transport, cargo must be secured at the sides at 80 percent of its weight force. I consider this requirement to be particularly important since lateral movements in a ship may occur tens of thousands of times during a journey from Hamburg to New York.

Figure 7

Cargo must be secured at the sides at 80 percent of its weight force

During road haulage operations, peak stress values usually occur only once.

Back to beginning

Fit-for-purpose packaging

Before goods become cargo, they must be correctly packed. What does "correctly packed" mean? Packaging must protect the goods against the expected stresses. Every means of transport generates its own specific climatic and mechanical stresses. To design the correct packaging, it is necessary to know the route that the cargo is to take. Knowledge of the route makes it possible to identify the different climate zones – which I shall discuss later – and the acceleration forces of the different means of transport that need to be catered for.

In addition to these external factors, it is also necessary to take account of internal factors. For example, if cargo is to be stacked in a container then the packaging must be able to withstand the corresponding stack pressure.

Figure 9: Boxes |

Figure 10: Drum pallet |

The boxes in Figure 9 are scarcely fit for shipment, let alone stacking when packaged in such a way.

The cargo must not only be stowed securely in the container. It must also be secured in its packaging in a way that will withstand the stresses to which it is to be exposed.

Figure 11 illustrates a crate in which a machine was packed loose. The consequences of this error became evident even during precarriage to the stuffing centre. The crate was destroyed by the machine from the inside out.

|

|

|

Figure 11: Crate |

||

Fit-for-purpose packaging is the logical prerequisite for secure transportation. Unfortunately, however, the fact that this principle is too often neglected in practice regularly results in loss and damage. Only when the packaging is fit for purpose can the goods be considered to be cargo.

Back to beginning

Container selection and inspection

As early as when the order is placed, it is necessary to make sure that the container is suitable for the cargo. It is important to make sure that the container can cater for the required payload and possesses the necessary load-carrying capacity and the required volume.

If the correct container is available for loading then it is necessary to check whether it has a valid CSC plate or is involved in an ACEP program and that it is intact both inside and out, that it is properly sealed, free of odor and functionally operative. If the doors can be opened and closed, can the container be closed spray-tight after loading? Are the load securing points intact? Is the floor area clear, undamaged and free of protruding screws and nails which might damage the new cargo? Unfortunately, it is not usually possible to check below the floor.

To summarize, it is very simple to perform a check. However, it is often the easy things that do not receive enough attention and therefore result in considerable loss and damage.

|

This small hole was not discovered during the container inspection. As a result, the cargo of cigarettes was damaged by water infiltrations. The cost of the damage amounted to € 15,000. | Figure 12 |

| How could this hole have been discovered easily? Very easily: Someone goes in, the doors are closed and if light enters then that’s where there’s a hole. |  |

| Figure 13 |

Back to beginning

Load distribution and load planning

Load distribution

The loading capacity of a container is also referred to as line load. For example, an average 20-foot standard container has a line load of 6 tonnes. A 40-foot standard container may, for example, have a line load of 3 tonnes. However, containers with significantly higher line loads also exist. Flatracks have a significantly reinforced floor area. The side rails of a flatrack can be used directly. As a result, it is possible to accommodate much greater loads. If the line loads are not observed, the container will be damaged – in extreme cases, in the way seen in the following picture.

Figure 14 [Aaron Bar-Tor]

Photo of the month – October 2006

In this case, the line load was vastly exceeded. However, the problems are not just restricted to such extreme cases. Simple overloading which "only" damages the structure of the container is also problematic. This is dangerous because this type of damage often goes undetected. If a container that has already suffered damage in this way fails, for example in the bottom layer on the deck of a container ship, then the entire stack above it will collapse. A collapsed stack is no longer secured and can therefore move unrestrictedly. Every time the ship moves, the unsecured stack topples against the neighboring stacks like a wrecking ball. These cannot withstand such stresses for long and give way in their turn. This can result in the feared losses of cargo on container ships which can endanger the entire vessel.

Load planning

At this point, I should like to quote from the CTU packing guidelines:

"Loading should be planned before operations are started. This should make it possible to segregate incompatible cargoes and produce either a tight or secured stow, in which the compatibility of all items of cargo and the nature, i.e. type and strength, of any packages or packaging involved are taken into account. The possibility of cross-contamination by odor or dust, as well as physical or chemical compatibility, should be considered."

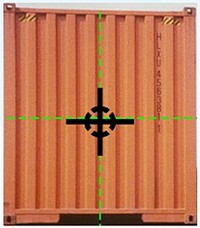

| This small extract indicates all the most important issues. The loading of cargo must be planned: Light on heavy, dry above wet. Gaps should be avoided under all circumstances since they endanger load security. The center of gravity should be located either at or in the immediate vicinity of the container’s longitudinal axis (Figure 15). |  Figure 15 |

| The load distribution in the longitudinal direction must be planned in such a way that no half of the container bears more than 60 percent of the payload (Figure 16). |

Figure 16

Hazardous goods must be stowed on the floor and the entire cargo must be correctly secured against the stresses. However, just adhering to these simple rules is an insoluble task for the majority of loaders and stuffing centers.

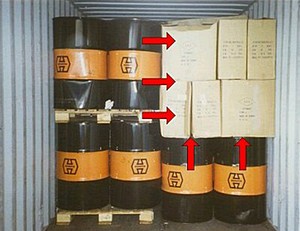

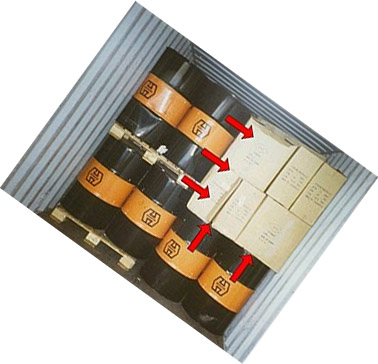

| If you want to stack barrels, then you need boards to use as intermediate layers. |  |

| Figure 17 |

|

And, as the following Figure illustrates, if you want to load barrels and boxes together then you have to provide material to protect the boxes. | Figure 18 |

| The next Figure indicates what will happen to the boxes in heavy seas. |  Figure 19 |

Proper load planning is the best protection against damage.

Back to beginning

Load securing in and on a container

The purpose of load securing is to ensure that the cargo remains in its intended position, suffers no damage itself and causes no damage to other cargoes. The best way of securing a load occurs when cargoes naturally fit tightly against one another. If this is not possible, then the loads have to be secured. During land transport, tie-down lashings are often used. These act exclusively through friction. Tie-down lashings are also known as friction loops since they rely only on friction. In the field of maritime transportation, direct lashings are preferred since movements may be repeated tens of thousands of times during bad weather.

Figure 20: Tie-down lashings (Friction Loop)

Figure 21: Direct lashings (Half Loop)

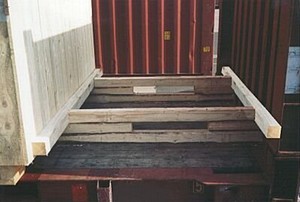

| The best mode of securing a cargo is bracing. If a tight fit cannot be established using the cargo itself, then it is a good idea to establish such a fit "artificially" using lumber. If bracing is not possible, direct lashings can be used. Although friction also makes a contribution here, it should not be accorded the same role in maritime as in land transportation. Anyone who secures a load takes on a great responsibility – not just for the cargo itself but also for the means of transport and all other users. |  |

| Figure 22 |

A number of practical examples show that good, correct load securing is only possible if the personnel involved have been well trained.

Figure 23

In Figure 23, it is clear that this equipment, weighing 25 tonnes, was secured at the sides only by tie-down lashings, that is to say by increasing the friction. A tie-down lashing can provide a securing force of approximately 300 kg (300 daN). Given a load of 25 tonnes, this is a very modest contribution. In contrast, a tie-down lashing can protect against vertical movements. However, this has little purpose here.

|

The tie-down lashings should be replaced with direct lashings, as shown in this Figure. These direct lashings directly counteract sideways slippage and thus the acceleration forces which occur during maritime transport. Depending on the quality of the belts and the securing points on the flatrack, this type of mechanism can provide a securing force of up to 10,000 kg (10,000 daN). This fact can have a decisive influence on the result of the transport operation. | Figure 24 |

An elaborate wooden skid can be seen in Figure 23. This structure makes it possible to set the machine part safely down on the flatrack. Wooden wedges were used to secure the cargo at the front and rear. The skid can absorb and withstand the 25 tonne cargo without any problem. However, at the front edges of the container, the nails in the wedges are intended to act as the securing elements. Unfortunately, the small number of nails used can, under optimum conditions, only secure between 1.5 and 2 tonnes. This is an absurd situation given that two wooden beams, only slightly larger than the wooden wedges, placed against the end wall of the container would make it possible to secure up to 20 tonnes. Lumber is one of the best cargo securing materials as it is able to absorb or transfer large forces and is very easy to process. Nails, on the other hand, can provide only a fraction of the securing force, are labor-intensive to put in place and, in the long run, destroy the floor of the container.

In the following photos, I want to present proof that inadequately secured loads can lead to catastrophic consequences.

Figure 25 [Ewig NYC for HDI]

(Photo of the month – August 2003)

A group of 18 containers was loaded with wire rod coils. As this Figure shows, these were "secured" only with wedges. Let us ignore, for the moment, the fact that the wedges were cut incorrectly and that the container floor was unsuitable for nails. What is important is that someone attempted to secure the not inconsiderable weight of the wire rod coils with wedges and nothing else.

| Such an approach is not just irresponsible. It also reveals a total misappraisal of the circumstances. On this ship, eight containers were lost overboard and the cargo in the remaining ten containers was a total write-off. These were the only containers to be damaged on this voyage (Figure 26). |  |

| Figure 26 [Ewig NYC for HDI] (Photo of the month – August 2003) |

The final example shows that even simple boxed cargo stowed to fit tightly against the sides of the container needs to be secured in the area near the door. One company that came to us for help had often found that containers that were backed onto the ramp with the door open lost their contents when the rolling shutter was closed (Figure 27).

Figure 27 (Photo of the month – October 2005)

|

The company’s solution to prevent this damage was to open the rolling shutter first. This is a flagrant infringement of load securing obligations. It puts the life of the person who opens the container at risk. The cargo must be stowed so stably that it cannot pour out of the container like bulk cargo. In addition, in the door area, it must be secured in such a way that nothing can fall out when the doors are opened. This can be achieved by using wooden lattices, pallets or belts. |

Figure 28 (Photo of the month – October 2005) |

Figure 29: Wooden lattice, wooden bracing

Back to beginning

Climatic stresses

Demanding climatic requirements must be met when transporting or storing goods with a high water content and/or of vegetable origin. Operators of general cargo ships were well aware of these requirements and monitored the temperature and humidity of the atmosphere in their holds. Thanks to targeted ventilation measures, it was possible to manipulate the storage atmosphere and prevent damage.

As containerization became more popular, first of all industrial, manufactured goods and then also goods of vegetable origin were transported in containers. It did not take long for humidity-related problems to appear since ventilation measures were no longer possible.

Figure 30: Climate zones across the world – Neef classification

During their voyages, ships frequently pass through a number of different climate zones. Journeys in a northerly or southerly direction are particularly problematic because the air and water temperature changes very quickly during such voyages. As the temperature changes due to the climate, so too does the microclimate in the container. The container climate is even influenced by daily variations in temperature. The term "daily variations in temperature" refers to the changes in temperature affecting the container due to different levels of solar radiation during the course of the day (i.e. day and night).

Back to beginning

Basic climatic terms

| The air always contains a certain amount of water vapor. Approximately 3 g/m3 in cold, dry air and more than 30 g/m3 in warm, moist air. This is only a small proportion, amounting to at most 3% of the mass of the air, but has a considerable meteorological impact as hurricane "Katrina", which struck New Orleans, demonstrated. |  |

| Figure 31 Hurricane "Mitch" [www.wikipedia.de] |

The crucial point is that the atmosphere can only contain a certain quantity of water vapor.

The saturation content depends on the temperature. That is why the moisture in the air is described in terms of relative humidity. The warmer the air is, the more water content it can contain.

Figure 32

Once the saturation content is reached, no more water can evaporate. Relative humidity at that point is 100%. A relative humidity of 60% means that air contains 60% of the saturation content.

The lower the relative humidity, the more water vapor the air is able to accept. Problems occur when the air that has previously taken in water vapor then cools down. The relative humidity then increases. Once the relative humidity reaches 100%, the water vapor condenses if the air cools any further. The so-called dew point has now been reached. If the dew point is reached in a container, water is deposited from the air and poses a significant threat to the cargo.

Many materials such as wood, paper, coffee, cocoa etc. are hygroscopic, i.e. they can take in humidity and then release it again. The quantity of water present in such materials is known as the water content. The water content is specified as a percentage relative to the dry weight of the materials.

|

The process of taking in humidity is known as adsorption and the release of water vapor as desorption. Sorption isotherms provide information about the specific behavior of different materials in response to humidity. | Figure 33: Sorption isotherm |

The diagram illustrates the typical "S-shaped" curves of a sorption isotherm for a hygroscopic material. The area between the two curves is known as the adsorption delay. It describes the delay in the adsorption of the water vapor by the hygroscopic material.

The higher its water content is, the more water vapor a hygroscopic material releases into the ambient air. This desorption continues until the air around the material has reached the equilibrium moisture content. This is the point at which the same water vapor pressure is present in the material and in the air.

Figure 34: Equilibrium moisture content

In simple terms, we can say that a material with a low water content in a container will generate a low relative humidity while a material with a high water content will generate a correspondingly high relative humidity.

If the air in the container becomes warmer, it automatically becomes relatively drier and can then take up more water vapor. If it cools down again, the relative humidity increases and the goods have to adsorp humidity. If they become too moist, condensation occurs because the dew point has been exceeded.

Figure 35: Cargo with a high water content

Figure 36: Cargo with a low water content

Back to beginning

Humidity management

A container is a closed space which has its own climate. If the container is airtight and no humidity can penetrate from outside, then its relative humidity depends only on the water content of its cargo and the temperature. The temperature is a variable that depends on the transportation route and cannot be influenced. Consequently, the water content of the goods is the only factor that can be regulated in order to control the container climate.

There are three humidity thresholds that are crucial for high-quality transportation. The first of these is the corrosion threshold.

| This is situated at a relative humidity of 40%. At between 40 and 60% relative humidity, ferrous metals are only mildly prone to corrosion. At higher levels of humidity, the likelihood of corrosion increases enormously (Figure 37). |  |

| Figure 37 Corrosion threshold |

|

The solution for goods that are liable to corrosion is to use a separate sealed package containing desiccants which keep the humidity below 40% at all times. | Figure 38 |

The next threshold is the mold growth threshold at 75 % relative humidity. This is the most important humidity threshold for the purposes of container transport. Mold may grow at a relative humidity of 75% or more. The factor regulating moisture in a container is the water content of the goods. Consequently, the water content must be chosen in such a way that the relative humidity cannot rise above 75% during transportation. It is necessary to take account of the daily variations in temperature and the route. One rule of thumb is that a water content which counterbalances an equilibrium moisture content of 60% can be considered safe.

However, all goods have their own specific water content at which transportation can be considered safe depending on both the route and the time of year. This state is known as container dry. At www.tis-gdv.de, we provide guideline values which help identify the container dry value for many goods.

When transporting goods that are particularly sensitive to moisture or in cases where extreme temperature fluctuations can be expected, it makes sense to choose a lower water content.

One way of preventing damage, for example, is to use passively ventilated containers which have perforated battens for passive ventilation in the floor and roof (Figure 39). If vegetable material cannot be dried to a safe water content then this type of container should be used.

Figure 39

If the dew point is exceeded due to high levels of humidity or extreme temperature fluctuations then the third and most dangerous threshold is reached – the dew point. It then rains in the container. If this continues for only a short time then suspended nonwoven fabrics may prove very useful in intercepting the moisture dropping from the top of the container. If it carries on raining for longer then damage to the cargo is a certainty (Figures 40 and 41):

Figure 40 |

Figure 41 |

Desiccants were used to try to cope with the moisture occurring in this container. A 20-foot container with 24 tonnes of cocoa with a 12% water content contains 2,880 kg of water. A few bags of desiccants are not going to solve the problem of humidity. The result was moldy cocoa.

The solution is to transport dry cocoa and, in particular during the winter months, use passively ventilated containers.

Back to beginning