4.1

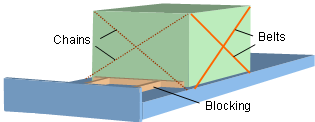

Direct securing in the longitudinal direction with belts and timber blocking

This example is intended to demonstrate

the incorrect assessment which may be made of a cargo securing arrangement when

using the conventional calculation method where securing devices with different

spring constants are loaded in parallel. Considering the cargo movement may reveal

the error.

A heavy cargo unit is secured against

sliding in the transverse direction with transverse, criss-crossed chains and

against sliding in the longitudinal direction with longitudinal criss-crossed

belts. The securing arrangement is largely symmetrical. Due to the greater

requirement for securing against forward sliding, blocking against the end wall

of the loading area with two pieces of squared timber is additionally provided.

The two lengthwise wooden shores press against transverse pieces of squared

timber of identical cross section. The cargo unit itself stands on flat wooden

boards.

Figure

17: Securing a heavy item against forward sliding

This example solely investigates securing

against forward sliding. At best, the chains contribute to securing in the

longitudinal direction by their pretension which increases friction. However,

since they are only pulled "hand tight", this is not taken into

account.

Cargo mass m = 18 t, dimensions l x b x h = 5,0 x 2,4 x

1,9 m, m = 0,3

| 4 belts lengthwise: | X = 4,9 m, Y = 0,0 m, Z = 1,8 m; L = 5,22 m

|

| | LC = 25 kN, elongation at LC = 4,5%, pretension F0 = 2,5 kN |

| 2 lengthwise wooden shores: | Cross-section 9,6 x 9,6 cm, LC = 2 × 92 kN, L = 2,2 m

|

| 2 wooden crosspieces: | Cross-section 9,6 x 9,6 cm, LC = 2 × 27,65 kN

|

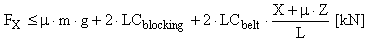

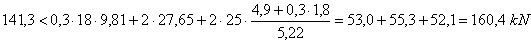

The external force is determined as

conventionally agreed.

FX = cx × m ×

g = 0,8 × 18 × 9,81 = 141,3 kN

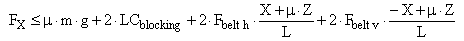

Conventional assessment of the securing against forward sliding:

According to the conventional assessment,

this securing exceeds requirements by a good 13%, if, as conventional, the load

LC is used for each securing device..

Taking account of cargo shifting:

In the present case, the blocking is

clearly the more rigid securing device. Using the previously described

selective method, the distance by which the cargo has shifted forward when the

blocking has reached the LC of 55.3 kN is first calculated. The spring constant

of the blocking is required for this purpose.

The blocking consists of two parallel

lengthwise wooden members, each 2.2 m in length, with two serial wooden

crosspieces, each 9.6 cm in thickness. The modulus of elasticity is 1100 kN/cm2

when loaded lengthwise and 100 kN/cm2 when loaded perpendicular to

the grain. The following spring constants are thus obtained:

| Lengthwise wooden member: | DL = A × E / L = 9,62 × 1100 / 2,2 = 46080 kN/m |

| 2 wooden crosspieces: | DQ = A × E / L = 9,62 × 100 / 0,192 = 48000 kN/m |

Arranged in series, the following value

is obtained for one wooden member, D = D1 × D2 /(D1

+ D2) = 23510 kN/m, the value for both of the wooden members being

twice that, or 47020 kN/m. This results in the cargo shifting by DL = DF / D = 55.3 /

47020 = 0.0012 m = 1.2 mm. Since the wooden members are placed horizontally,

this is also the offset DX of the cargo unit.

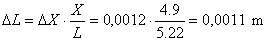

As a result of the offset DX, the rearward

pointing belts are extended by the amount

The spring constant

of the belts amounts to DG = DF / DL = 25 / (5.22 × 0.045) = 106 kN/m. As a

result of the elongation by 0.0011 m, the rearward pointing belts increase

their tensile force by DF = DG × DL = 106 × 0.0011 = 0.117 kN from 2.5 to 2.617 kN. The

forward pointing belts reduce their tensile force by the same amount from 2.5

to 2.383 kN. They thus still pull forward and assist the longitudinal force FX.

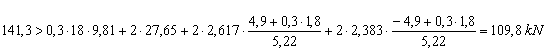

Both values are inserted into a balance:

The balance is not at

equilibrium. The shortfall is a good 22%. In the stated load case, the blocking

would be overloaded and could even reach the critical buckling load. By way of

remedy, it is proposed to construct the blocking with four instead of two

lengthwise wooden members, so that they can alone provide forward securing

together with the friction.

|