1.1

Full braking

Full braking is the greatest load to

which a forward securing arrangement is exposed. Recent developments in the

field of truck tires, coupled with modern brake systems and asphalt roads,

permit braking deceleration values that are perfectly capable of approaching

0.8 g

(1).

Other factors, such as the distribution of axle weights, also play a role in

this context.

The connection between the loading area

of a truck or semitrailer and the tyre footprints is not rigid but resilient,

which means that the inertial force of the cargo does not follow directly from

the braking deceleration, but instead initially brings about a forward tilting

of the loading area. This "pitching angle" is not at a steady state

throughout full braking, but has pitching oscillations superimposed on it. The

amplitude of the pitching oscillations is very highly

dependent on buildup time, i.e. the time taken for the braking force to increase

to its full value.

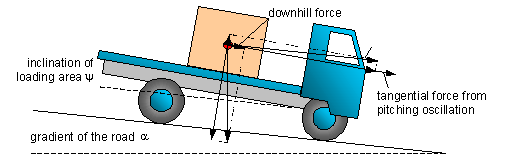

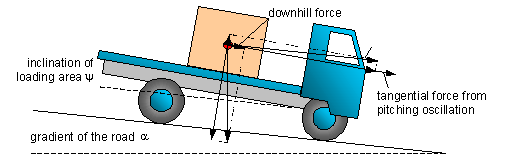

During full braking, the following forces

act forwards on the cargo in the coordinate system of the loading area

(parallel to the loading area):

- inertial force component from the braking maneuver,

- downhill force (weight component) arising from

the geodetic inclination of the loading area (pitching angle and gradient of

road),

- inertial force arising from tangential

acceleration from superimposed pitching oscillation.

The normal force acting from the cargo on

the loading area is generally reduced by two causes, namely, as a result of the

inclination of the loading area, by the

- upwardly directed vertical component of the inertial force,

- reduced normal component of the weight-force.

The upwardly

directed vertical component of the inertial force, and the reduced normal force

arising from the geodetic inclination of the loading area reduce both the

friction relative to the loading area and the moment of stableness of a cargo

unit.

Figure 1: Full braking on downward sloping road

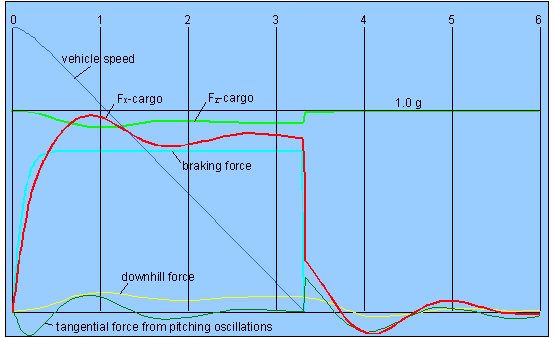

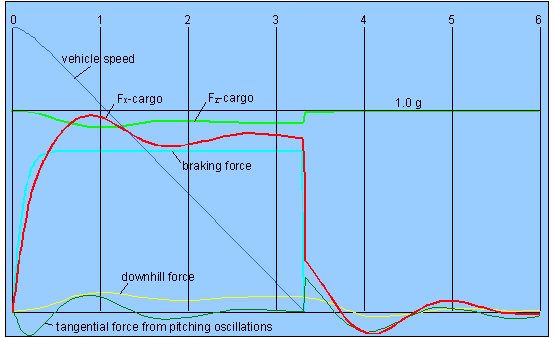

Figure 2: Full braking on a level road from 90 km/h with 0.8 g braking deceleration

and

0.3 s buildup time; stopping distance = 42.9 m

Figure 2 shows the numerical solution of

the equations of motion over a period of 6 seconds. The forces acting on the

Cargo have been converted into units of g. The vehicle is stationary after

approx. 3.3 seconds.

The truck is loaded in such a way that,

at 0.8 g deceleration, a steady-state pitching angle of 4° is obtained. The

maximum pitching angle after 0.9 seconds amounts to 5.5° as a result of the

superimposed pitching oscillation. This oscillation is strongly damped and

largely subsides by the time the vehicle is at a standstill, but is re-excited

by the familiar jerk at the end of the braking maneuver.

The maximum longitudinal load on the

cargo at 0.9 seconds amounts to 0.98 g, at which point the normal force has

simultaneously declined to 0.92 g.

Numerous further simulated full braking

maneuvers at other speeds, uphill and downhill road gradients and other vehicle

types (e.g. semi trailer with a smaller pitching angle) reveal similar

profiles. The following general conclusions may be drawn:

- Calculating on the basis of braking force transfer corresponding to

0.8 g, cargo securing must be designed for just about 1.0 g, because the

downhill force from the pitching angle plus the tangential force from the

superimposed pitching oscillation add about 0.2 g.

- Full braking from lower initial speeds results in only

insignificantly more favorable results. Only at speeds of below 15 km/h may it

happen that the vehicle is already stationary before the maximum longitudinal

force has been reached.

- Semi trailers, which are assumed to have half

the pitching angle, experience approx. 3% lower longitudinal forces and a 4%

lower reduction in normal force. The outcome is no more favorable than this

because the pitching oscillation period simultaneously becomes shorter and the

amplitudes of the pitching oscillations are only insignificantly smaller than

in a vehicle with a 4° steady-state pitching angle.

- The more rigidly is a loading area mounted, i.e.

the less it responds to deceleration with a pitching angle and with pitching

oscillations, the closer the longitudinal force acting on the cargo

approximates to the pure inertial force from the braking deceleration.

- Gentler braking maneuvers with buildup times of

longer than 2 seconds result in virtually no superimposed pitching oscillations.

Calculating on the basis of 0.8 g maximum braking deceleration, the only

further allowance which need be made is for the parallel component of the force

of gravity from a steady-state pitching angle. The allowance is obtained from

the sine of this angle.

- On full braking uphill from a speed of 50 km/h,

the braking force is increased by the backward downhill force and, as a result,

the braking distance is distinctly shorter than on a level road. The effective

pitching angle is, however, reduced by the rearwardly directed inclination of

the road, such that the difference in longitudinal force on the cargo is almost

equalized compared to the situation on a level road. Under the selected

conditions according to Figure 2, the cargo should be secured against acceleration

of 0.99 g.

- On full braking downhill from a speed of 50

km/h, the longitudinal force on the cargo is somewhat smaller than in the event

of full braking on a level street. The effective braking force is smaller and

the braking distance greater. The downhill force is, however, increased by the

inclination of the road. Under the selected conditions, the cargo should be secured

against acceleration of 0.96 g.

- Calculation methods for dimensioning

longitudinal cargo securing should take suitable account of the decrease in

normal force (weight).

|