| Classes of mechanical stresses | [German version] |

| Dynamic stresses | |

| Static stresses | |

| Other mechanical stresses |

Dynamic stresses

Units of measurement and formulae:

The dynamic force (F in [N]) acting externally on a cargo is calculated by multiplying the mass (m in [kg]) by acceleration (a in [m/s²]):

| F = m × a [N=kgm/s²] |

Acceleration (a) is calculated by dividing

velocity (v in [m/s]) by time (t in [s]):

| a = v / t [m/s²] or |

distance (s in [m]) by time squared (t² in [s²]):

| a = s / t² [m/s²] |

Acceleration at curves (acurve) is calculated by dividing velocity squared (v² in [m²/s²]) by curve radius (r in [m]):

| acurve = v² / r [m/s²] |

Impact stresses are mechanical/dynamic stresses, which are caused by acceleration or deceleration of masses, and, though not generally repeated at regular intervals, do occur more or less frequently and with varying intensity during transport, handling and storage operations.

| Vertical impact: Free fall (dropping), tipping (by exceeding tilting moment), tumbling (rolling edge over edge), bumping (during hoisting, abrupt setting-down or bumping by other cargoes) | |

| Horizontal impact: jolting impacts (during switching), bumping against vehicle walls or other cargo (centrifugal forces at curves and when travelling through switches, starting up) |

Impact stresses are generally stated as a multiple of acceleration due to gravity (g = 9.81 [m/s²]).

Vibratory stresses, measured as [Hz] are the vibrations generally arising at the payload areas during movement of the means of transport, which are transmitted to the cargo in the form of horizontal and vertical impacts.

| Vertical impact: occurs during movement of the means of transport, shaking, chafing (vehicle running) | |

| Horizontal impact: occurs during movement of the means of transport (unevenness of travel way) |

Other dynamic stresses are localized impact stresses: abrasion (dragging, pushing, pulling) or chafing (friction).

Dynamic stresses experienced in the various means of transport in g [m/s²]

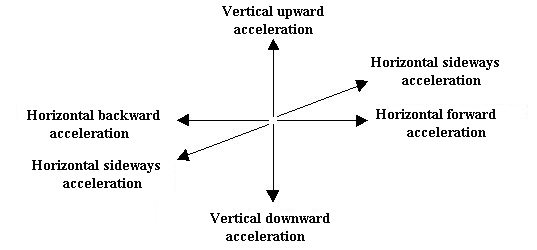

| Type of acceleration: |

|

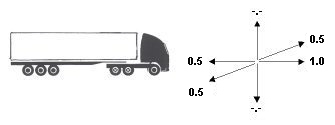

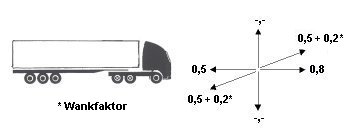

Stresses in road transport:

acc. to CTU packing guidelines: |

acc. to VDI Guidelines, guideline 2700 ff.: |

| acc. to Hafenfachschule Bremen: Details relating to combined sea-road-sea transport operations  |

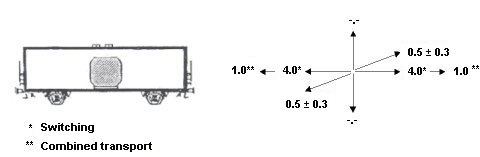

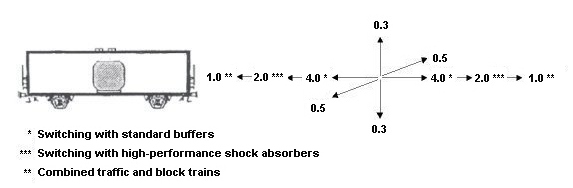

Stresses in rail transport:

acc. to CTU packing guidelines: |

acc. to GDV: |

Eastern European rail transport uses semiautomatic coupling systems. To initiate the coupling procedure, these couplings require a minimum speed of 9 km/h. Since these coupling procedures are frequently performed at higher speeds due to corrosion, accelerations of up to 10 g and in exceptional cases even up to 18 g may occur.

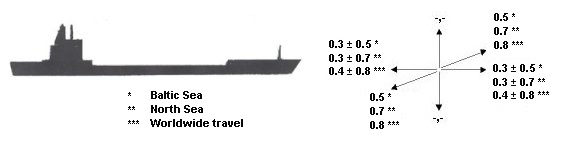

Stresses in maritime transport:

In maritime transport, the accelerations to be expected depend on the ship’s dimensions and shape, its center of gravity and center of buoyancy, its cruising speed and linear and rotational movements or the interaction of several of the above-stated movements. Examples of the movements experienced by a ship at sea are contained in the CTU packing guidelines.

acc. to CTU packing guidelines: |

|||||||

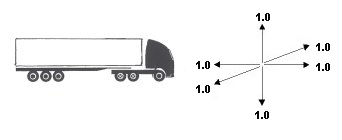

acc. to GDV: in maritime transport, calculations should always be based on the least favorable assumptions. Acceleration values of 1.0 g should therefore be assumed. This also applies to securing measures relating to cargoes transported by sea in containers, road vehicles, freight cars and trailers. |

|||||||

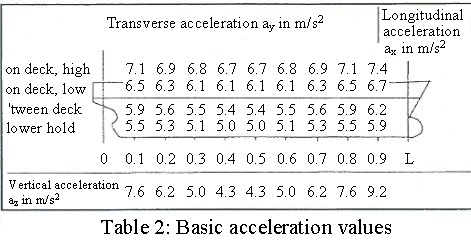

| acc. to German Federal Bulletin:

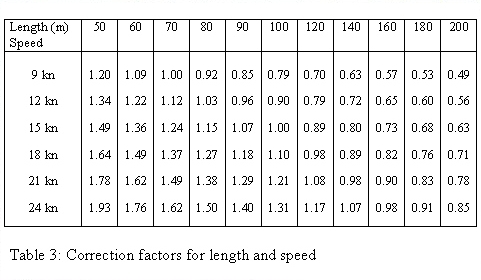

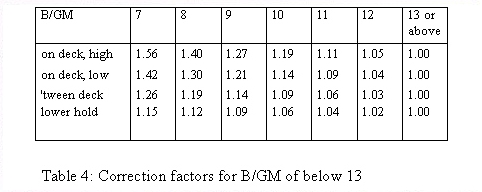

The guideline entitled „Bekanntmachung von Änderungen der Richtlinien für die sachgerechte Stauung und Sicherung von Ladung bei der Beförderung von Seeschiffen“ („Publication of amendments to guidelines for the correct stowage and securing of cargoes for carriage in ocean-going ships“), 14th February 1996, contains in table 2 the basic acceleration values in m/s² for the various deck areas and lengthwise portions of a ship. Tables 3 and 4 contain correction factors for other ship lengths and speeds together with the ratio of width and metacentric height. German Federal Bulletin, 07.05.1996, no. 85a, volume 48, page 6

* kn = knots  ** B/GM = width of ship in relation to its metacentric height |

Stresses in inland waterway transport:

The accelerations arising in inland waterway transport are negligible and may be calculated on the basis of the stresses arising in road transport.

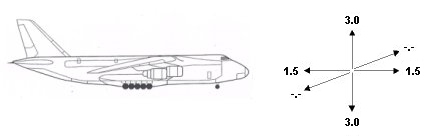

Stresses in air transport:

acc. to Delvag Luftfahrtvers. AG: |

Stresses during cargo handling:

During cargo handling, stresses of 1.0 g may be assumed. Jerky lifting and setting down may generate higher g values.

Back to beginning

Static stresses

Units of measurement and formulae:

Pressure (p in [N/m²]) acting externally on the cargo is calculated by dividing static force (F in [N]) and area (A in [m²]), static force being calculated by multiplying mass (m in [kg]) and acceleration due to gravity (g in [m/s²]):

| p = F / A [N/m²], wherein F = m × g [N=kgm/s²] |

Compressive stresses arise as a result of stacking items of cargo on top of one another or by contact pressure exerted by transport, handling and storage equipment: squeezing, pinching, chafing, walking over, headwind, squashing (stacking, dragging, friction, by workers and handling equipment).

Back to beginning

Other mechanical stresses

such as electrostatic charging, sound wave stress, radioactivity: bangs, noise, radiation (destruction by pressure waves).

Back to beginning