| Photo of the month – January 2021 |

[German version] |

| To welcome in the new year, we are pleased to bring you two columns. |

|

|

|

| Evasive action | Poor securing goes before a fall |

Evasive action

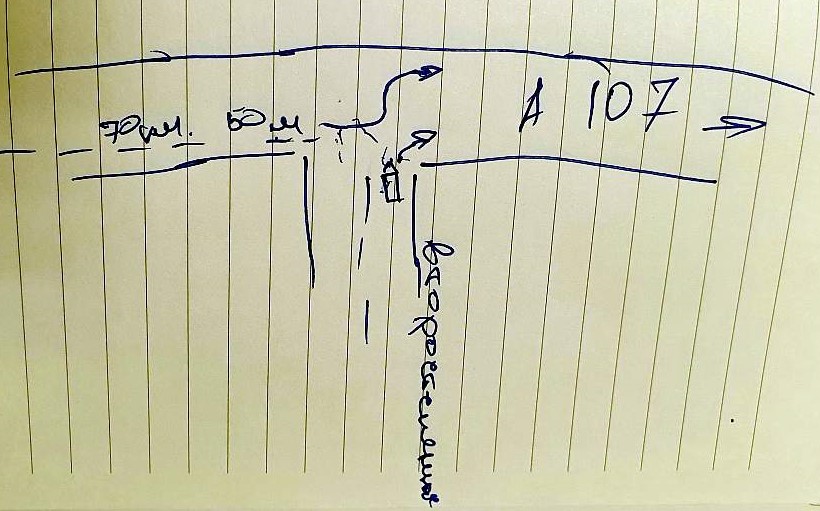

Diagram 1 [Viktor Smuhunov / Captain Anatoly Shmelev]

We received this diagram from our colleague Captain Anatoly Shmelev in Belarus. It shows the consequences of swerving to avoid an accident. And such consequences may just as well have been noted in Germany, South Africa, Brazil, China, Australia or anywhere else, and not just in Belarus, as the laws of physics apply everywhere.

An articulated truck suddenly has to swerve to avoid a vehicle approaching from the right. The load of four 5-tonne coils was not adequately secured and by and large continued traveling in the same direction.

Figure 2 [Viktor Smuhunov / Captain Anatoly Shmelev]

This is what the loading bed looked like after the accident.

- The first thing we notice is that it is empty.

- Then we see the wet skid marks that are more or less parallel and swerve off to the right.

- And then we note the remains of the belts lying on the loading bed in pairs, clearly sliced clean through.

- And if we look a little more closely, we can see what appears to be a few small stones. The end wall appears to be pretty strong and only has a few small dents, which is not surprising, as the coils fell off the loading bed before they collided with the end wall.

Figure 3 [Viktor Smuhunov / Captain Anatoly Shmelev]

On closer inspection, we see that what appeared to be small stones is probably actually snow or slush. The fragments of wood by the end wall confirm our impression.

Figure 4 [Viktor Smuhunov / Captain Anatoly Shmelev]

Figure 4 shows the side road that joins the main road from the right. The coils are lying on the road in this area.

From this evidence, we assume that the accident happened as follows:

- The truck driver sees that a car is about to pull in front of him (the right of way could be seen from the road markings) and immediately started emergency braking.

- He saw that braking alone would not be enough to prevent the accident and swerved to the left.

- The coils break free even as the truck starts to brake, as the dreadful level of friction (between wood and the textured, coated board of the loading bed) is reduced even further by the snow under the skids and provides virtually no securing force. This is what caused the straight, wet skid marks on the loading bed.

- The belts are arranged as seen in Figure 5. Without any edge protectors! And this is why the initial high load applied to them as a result of the emergency braking maneuver caused them to tear or be sliced through by the sharp edges of the coil packaging.

- The driver swerved to the left while the coils were slipping in the direction of travel. And the laws of physics dictated that the coils simply continued to move in the same direction, which was now to the right of the vehicle.

- They broke through the tarpaulin, damaged the stanchion and the end wall and landed on the road.

- We have no information as to whether the driver who ignored the right of way of the truck paid for his carelessness with his life, but the photos suggest that he was very lucky.

Figure 5 [Viktor Smuhunov / Captain Anatoly Shmelev]

This is how the coils were secured before the accident.

How to secure the load:

- The snow under the runners of the skids must be completely removed. If this cannot be done reliably, the load must be secured without the help of friction, and that takes a lot of effort.

- If we can use friction, it is simple: We take anti-slip mats and place the skids on these. The mats must protrude beyond the skids, particularly to the front, as direct lashings only restrain the load after it has slipped a little.

- A coefficient of friction µ of 0.6, which leaves 0.2 g still to be secured.

- 0.2 g x 5000 daN weight force gives a required securing force of 1000 daN.

- One belt arranged as a direct lashing through the eye of the coil provides 2 x 2000 daN of securing force minus any effect of the angles involved.

- Edge protectors are an absolute must! Ideally, these should be protective sleeves, semicircular PU guides or similar.

- But beware: If we want to fully exploit this level of friction for securing, the connection between the coils and the skids must also provide the same level of security.

Figure 6 [Viktor Smuhunov / Captain Anatoly Shmelev]

- The connection to the skid is established on the one hand by the tight fit to the oblique lumber and by the two steel straps on the other.

- Because the coils have been loaded facing the direction in which they would roll, we would not entirely trust the strength of this connection.

- And so, we would recommend the following:

- Anti-slip mats under the skids

- Two belts (of the same length, but attached to different lashing points) passed through the eye of the coil as loop lashings to the rear and one loop lashing to the front.

- If there is any snow involved, either on the loading bed or under the runners of the skids, direct lashings must also be used to secure the load to the sides.

Figure 7 [Viktor Smuhunov / Captain Anatoly Shmelev]

Brand new direct to the scrap heap.

Your load securing columnists wish you a happy, healthy and safe 2021

Back to beginning