| Photo of the month – October 2025 |

[German version] |

Imagine you are driving through town, thinking nothing bad is going to happen … and then you see this!

Figure 1 – [Dye Matthias Böhmen]

This contribution to our “Photo of the month” column once again shows that everyone can join in. We invite all our readers to send in their photos, which will then in turn encourage other readers to improve the way they secure their loads.

So what can we actually see here?

View from rear left:

Figure 2 – [Dye Matthias Böhmen]

View from right of center:

Figure 3 – [Dye Matthias Böhmen]

Looking through the pipes, we can see that other material has been loaded in front of them. Unfortunately, we do not know if whatever is in front of the pipes has enough compressive strength to withstand the load if the vehicle brakes.

There might be something solid on the left, next to the left pipe. There is nothing next to the pipe on the right. The width of the two pipes together is less than the width of the loading surface between the side walls.

The pipes were secured by passing lashings over the top of them. That is to say, using “tie-down lashings”. A total of three belts were used: one guided over the side wall and the other two hooked into load securing points on the loading surface.

Let us take a quick look at the load securing to the side:

Load securing is adequate whenever the securing forces are greater than the forces that arise. The following example illustrates the force balance calculation that can be assumed when braking.

Arising forces< Securing forces

Arising forces < Friction + securing

0.5 x m x g< m x g x µ + n x k x TF x µ x sin(a)

However, round loads pose a particular problem: They roll over the friction-inducing substrate. As a result, the coefficient of friction µ to be used in any load securing calculation is “0”. Which gives us in practice:

0.5 x m x g < m x g x 0 + n x k x TF x 0 x sin(a) 0.5 x m x g < 0 + 0

This makes it clear that any force that arises with an assumed mass is always greater than 0. There is therefore no load securing.

Beyond this, it is interesting to note that if the load is simultaneously subjected to lateral and longitudinal acceleration, then friction is also not effective for securing it in the longitudinal direction. In the event of lateral motion, the load will again move across the friction-inducing substrate in the longitudinal direction.

Since there is no other load securing at the back in the current example, acceleration of this sort would cause the two pipes to slip off the loading surface to the rear.

What is more, this problem also occurs if the pipes do not slip all at once and the total slippage gradually accumulates as the sum of a series of smaller movements.

What could have been done better?

- Round loads should be transported lying down in saddles or between fixed wedges. Sufficient friction-enhancing material must be placed under the saddles/wedges to ensure a high coefficient of friction.

- Friction-enhancing material should also be used on these saddles/wedges. Since no sideways rolling should occur on the saddles/wedges, the coefficient of friction can also be used to calculate the load securing in the longitudinal direction.

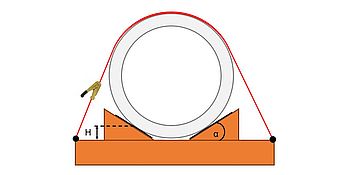

- Saddles or wedges should climb by an angle (a) of at least 35° from the horizontal. This eliminates the problem of the round material rolling out of the saddles/wedges when subjected to maximum lateral acceleration. The support height (H) depends on the pipe diameter. For a diameter of 1 m, the support height should be at least approximately 6 cm.

- To provide adequate securing force in the direction of travel, it is then possible to use tie-down lashings – even though we are known to favor direct lashings and would prefer a suitable head loop or blocking mechanism.

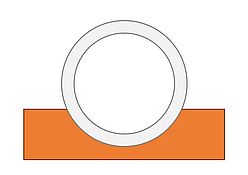

Round load in a suitable saddle:

Diagram 1 – [GDV & KLSK]

Round load between wedges:

Diagram 2 – [GDV & KLSK]

Your load securing columnists wish you all a safe autumn!

Back to beginning