| Photo of the month – February 2024 |

[German version] |

Drums…leave them like that!!

They’re heavy enough already…

Unfortunately, that’s something we hear all too often. Even now! “It’s so heavy, it’s not going to shift.” To which we always respond:

- So how is the truck able to transport it?

- Answer: Because it’s got 450 hp.

- Next question: And what sort of brakes do the truck and its trailer have?

- Answer: Fantastic disc brakes, of course!

- Our turn again: and what sort of brakes does the load have?

If it hasn’t done so before, the conversation now starts to get a bit trickier and we explain: - The truck and trailer have rubber tires and brake extremely well on the rough road surface. However,

- the load consists of steel standing on rough-sawn lumber

By this point, the error in the thinking has (usually) become clear.

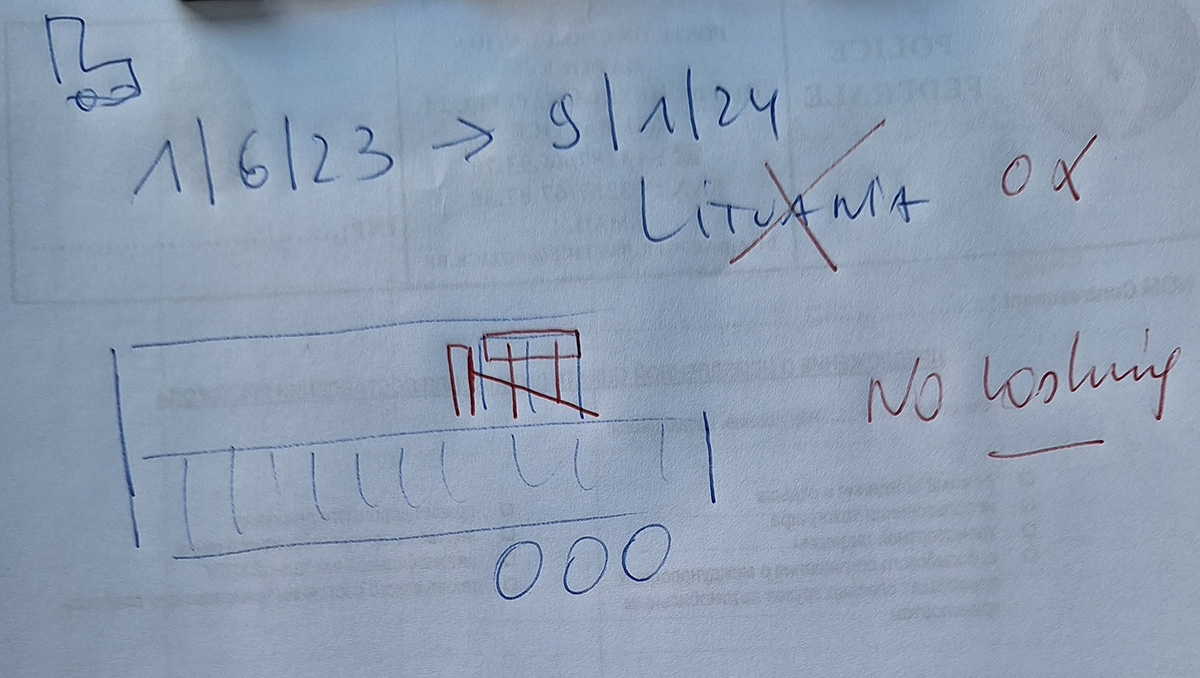

Diagram 1 [Raymond Lausberg]

The sketch made by the officer at the scene speaks volumes. The load is drawn in and that in the top layer is highlighted, and next to it the note in red: “No Lashing” more or less says it all. There was no load securing anywhere – neither in the bottom layer nor in the top one.

Figure 1 [Raymond Lausberg]

The load is just standing there in the trailer without anti-slip mats and without even a single belt. The job of securing the load to the rear is entrusted to a single locking bar. This securing method relies on the friction of the tensioner against the removable slat. The bracket has been pressed against the removable slat using the locking bar tensioner. Some friction-enhancing material has been applied at the bracket. The securing effect consists almost exclusively of the following force:

Pretensioning of the bracket times the friction of the bracket at the removable slat. If everything goes according to plan then a locking bar like this can exert a securing force of approximately 200 daN. As the friction of the load is 0.3, it is still necessary to apply a securing force of 0.2 to the rear. This corresponds to 4,800 daN. Even if the lumber is very rough and we assume 0.4 µ, we are still missing 2,200 daN to the rear.

Figure 2 [Raymond Lausberg]

Figure 3 shows that the load was indeed standing in the trailer without being secured in any way. The top layer of the load is particularly striking. The plastic strap around the top third of the drums simply makes sure that the load cannot slip from the pallet while being transported by fork-lift truck. The drawing made by the officer at the scene provides a good indication of how these loads can be secured. The load simply has to be secured in and against the direction of travel.

Figure 3 [Raymond Lausberg]

The bottom layer is not secured in any way, meaning that only friction can be taken into account. If we assume µ = 0.3 then the end wall is left to secure 12,000 daN. If we are dealing with a Code XL vehicle then it is able to do this. So all we need to do is make sure that the drums are secured to the side because they don’t quite fill the space in the trailer. If the vehicle accelerates in the direction of travel, there is a risk that the drums will slide in against one another and push out the sides of the trailer and/or the system of removable tarpaulin slats. If you’d like to know what the result might look like then take a look at the Photo of the Month for August 2013.

Figure 4 [Raymond Lausberg]

What makes matters even worse is that plentiful load securing equipment was present in the vehicle but not one bit of it was used.

Figure 5 [Raymond Lausberg]

If we consider the momentum the eight drums on the top layer could have developed once they got moving then the blind faith in Providence shown here is truly astonishing.

Your load securing columnists as always wish you a safe journey.

Back to beginning