| Photo of the month – December 2021 |

[German version] |

A host of guardian angels came down!

In this season of Advent, where we are filled with a sense of spirituality, hope and a belief in a better world, we have found proof not only that guardian angels really exist, but also that they were absolutely on the ball this time. So how did we come to this conclusion? Because the driver of this articulated truck escaped injury.

Figure 1 [LYBAERT DEPANNAGE GENT – Lausberg, Raymond]

He certainly got the fright of his life, and perhaps he has come round to the idea that sheer weight does not make a load secure. But sadly, this superstition (that’s so heavy that it simply can’t slip) is well entrenched. Sometimes it seems that the human imagination is not capable of grasping that a mass that cannot be moved by a person is perfectly able to move on its own, and particularly so during a braking maneuver. The fact that 400 to 500 horsepower (and sometimes more) are available for transporting the load and that the latest generation of disc brakes are used for braking seems to be quickly forgotten. Perhaps a load-securing course would remind people and even hammer it home so that it is not forgotten.

By starting with this picture, we are working our way backwards, i.e. starting with the consequences. To give our readers a better idea of how this end wall came to be destroyed, here are the “culprits”.

Figure 2 [LYBAERT DEPANNAGE GENT – Lausberg, Raymond]

Unfortunately, we do not have all the documentation for this case, so we will have to improvise a bit. In Figure 2, we can see pipes that were stacked using intermediate dunnage. But at the moment, we can’t see the counterpart of this dunnage on the loading bed. We don’t know exactly how the pipes were stowed there…

Figure 3 [LYBAERT DEPANNAGE GENT – Lausberg, Raymond]

Figure 3 suggests that there were only two pieces of dunnage, one on the loading bed and one under the second layer. But Figure 4 sheds some light on the matter:

Figure 4 [LYBAERT DEPANNAGE GENT – Lausberg, Raymond]

Here, we can clearly see that the bottom layer has slipped off the dunnage, which is now lying behind the pipes. However, we have no idea where the rearmost dunnage from the upper layer is (if indeed it ever existed). And we also don’t have any pictures where we could look for any marks that may be present that would indicate slippage.

Load securing:

25 tonnes of pipes, seven in total weighing 3.6 tonnes each, were “secured” with tie-down lashings. We don’t know how many belts were used, but we assume that there were 8 or at most 10 tie-down lashings. The really interesting thing here is the coefficient of friction, because we are dealing with steel with a film of rust, resting on sawn softwood, which is in turn resting on textured, coated board with sheet steel inserts. If there was no dunnage at the rear of the second layer, then the friction pair at this point is steel on steel coupled with steel on softwood in places. The dunnage has slipped on the loading surface and on the load itself. The pipes certainly slipped off the dunnage at the rear and were able to generate or maintain sufficient kinetic energy relative to the loading bed to destroy the end wall and penetrate the driver’s cab. Given the rather unfavorable friction pairing, we assume a maximum coefficient of friction μ of 0.3. At a pre-tensioning force of 800 daN (STF 400 daN) per lashing, we get 8000 daN x 0.3 = 2400 daN of securing force with 10 lashings (ignoring the angles). However, this load would have required 12,500 daN of securing force (25 t x0.5 = 12,500 daN).

Securing to the sides:

We have another fundamental problem here. The nails in the wooden wedges are the only way in which the load is secured to the sides. These provide a maximum of 400 daN securing force with the following provisos:

- Nails of at least 5 mm diameter must be used,

- The nails must penetrate through the wedge to a depth of at least 5 cm,

- The nails must penetrate into the underlying surface by at least 4cm,

- One nail must be driven in as a tension nail and

- A maximum of two nails must be driven in as holding nails.

The tension nail ensures that the wedge is in contact with the load and the two holding nails “secure” the load. Given that two wedges are used, this yields 1600 daN of securing force to the sides (but also only on the dunnage). This load requires 12,500 daN of securing force to the sides, in which case around 13 % of the securing force has been provided by the wedges.

Note on nails in wedges:

If more than three nails of the size given above are driven into wedges, this impairs their stability. There is a risk of them splitting.

How would we have secured the load?

- The pipes would have rested on sandwich elements (anti-slip material / wood / anti-slip material).

- Wedges would certainly have been used as a safety measure during loading and unloading.

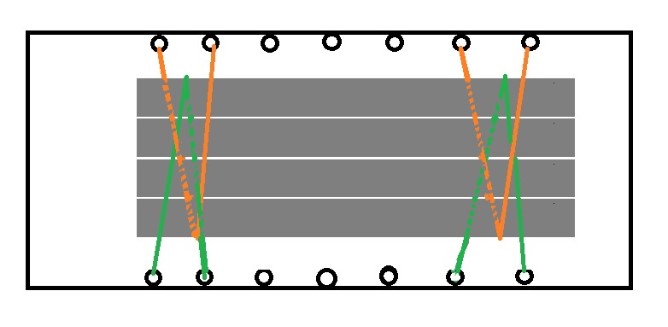

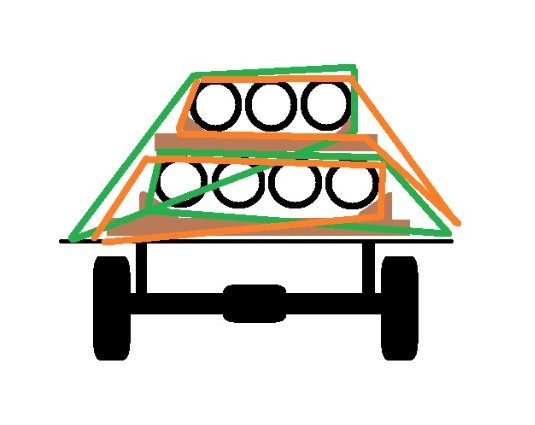

- Both layers would have been secured to the sides with four loop lashings each. (See Diagrams 1a and 1b)

Diagram 1a [TIS]

Diagram 1b [TIS]

- High point and line loads are to be expected, so it is essential to use heavy-duty anti-slip material.

- Pre-tensioning the loop lashings adds another 3200 daN of pre-tensioning force, which gives a securing force of 1920 daN, but this is strictly kept in reserve.

- We would use direct lashings to take care of the missing 5000 daN of securing force to the front. To achieve this, we have always built an artificial end wall in past Photos of the Month. This would also be an option here, although it would involve a considerable amount of effort. However, this load opens up another securing option.

- We need four chains, each of which is a good three meters longer than the load, and maybe four lifting slings.

- An even front face to the load is established in the first and second layers.

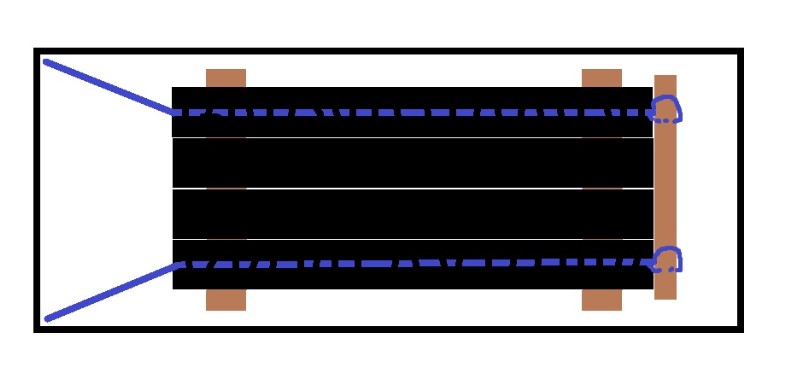

- Two chains per layer are passed through the outer pipes and passed around a piece of squared lumber or attached with a sling to the piece of squared lumber lying or hanging in front of the load. (See Diagram 2)

Diagram 2 [TIS]

- On this vehicle, the chains can be attached either on the loading bed (provided the apertures we can see there are suitable for use as load-securing points) or to the load-securing points, plenty of which are present on the side of the trailer.

- Don’t forget to pre-tension the chains!

- If belts are used instead of chains, they must be protected from the sharp edges of the pipes.

Figure 5 [LYBAERT DEPANNAGE GENT – Lausberg, Raymond]

But we completely fail to understand how a loader, who has the same responsibility as the driver, can send such a dreadfully secured vehicle out onto the roads. What would have happened if the driver had been injured or killed?

- The court dealing with the case would have looked into who, apart from the driver, was responsible for securing these pipes.

- 1. The carrier and/or freight forwarder. Since the vehicle was suitable for transporting this consignment and also had sufficient load securing equipment on board, they are both off the hook.

- 2. The loader! It is the loader who allowed the driver onto the roads with a load that was completely inadequately secured and was criminally negligent in failing to meet their responsibilities. They should have ensured that the load was properly secured. Whether the load is secured by the shipper’s employees or whether the driver is instructed to do so depends on the contractual situation between the carrier and the shipper. But the fact is that, in this theoretical case, the loader bears the full brunt of the responsibility.

If they have not delegated the responsibility properly and ensured that those responsible at the loading ramps can also fulfill their responsibility, it is they who will be in the dock, and if someone’s life has been lost, the penalty will generally be quite severe.

In this respect, everyone involved should be grateful that the guardian angels have once again excelled themselves.

We wish all of our readers a peaceful Advent!

Your load securing columnists

Wolfgang Jaspers and Uwe-Peter Schieder

Back to beginning