| Photo of the month – December 2015 – Christmas special 6 |

[German version] |

Silly Loop

Figure 1 [André Brusselle]

On this trailer, we can see three impressive lengths of steel that have been left in a large parking area at a ferry terminal. At first glance, we see five belts, clearly equipped with long lever ratchet handles, from each of which a hook is dangling. That was the first thing that caused our brows to furrow. One good thing to notice here is that edge protectors have been used throughout the load. The surfaces of these lengths of steel, which have clearly been transported directly from the steel mill, are still covered with very rough mill scale which can damage the belts.

Figure 2 [André Brusselle]

The first two figures do at least give the impression that the loaders thought very carefully about the overall center of gravity of the load. Even though we cannot measure it, it seems that the overall center of gravity of the three steel lengths is located exactly where it should be, just ahead of the first axle assembly.

Figure 3 [André Brusselle]

Figure 3 justifies a few more positive comments. Edge protectors have been used wherever the belts come into contact with the steel lengths. These protect the belts against the sharp-edged abrasive load and allow them to slide more effectively around the cargo. However, that is the last good thing we have to say about this load and the way it is secured.

The ratchet handles of all the belts are all problematic, as the dangling hooks indicate. They show that each belt used here was threaded through the ratchet handle, passed over the cargo as a round-turn lashing – or silly loop – and then inserted in the ratchet handle again on the opposite side (see Figure 4) before being tensioned on both sides. Fixing a ratchet handle on both sides and clearly pretensioning extremely well is, first of all, a lot of work and, secondly, the loaders clearly considered the question of load securing very seriously. Unfortunately, they decided to use a round-turn lashing – or silly loop. The term „silly loop“ speaks volumes because it describes an unintelligent way of tying up a load. In fact, the silly loop gathers the load into a bundle. However, the load is actually secured only by the relatively small tie-down force of the lashing and the friction of the belt against the cargo.

But just think what could have been achieved with 10 tensioners and 10 belts! In particular, if friction were to be taken into account properly during the implementation of the load securing measures. Although we do not know the dimensions of this load, the very fact that the supporting lumber, which has an estimated section of 12 x 12 cm, is bent upwards on both sides suggests that the vehicle is, at the very least, fully loaded. How much better it would have been if the anti-slip material, which has clearly been used at the ends of the lumber, had instead been laid underneath the entire length of the lumber. Even if the cargo is covered with rough mill scale, we do not know its friction against the timber. It would therefore under any circumstances have made sense to pass on the high friction of the anti-slip mats to the load itself. To do this, all that is necessary is to also equip the top side of the lumber that is used as dunnage here with anti-slip mats. Furthermore – and we shall never tire of saying this – it is not sensible to use square dunnage, because this tends to roll if the vehicle accelerates in the direction of travel. Instead, rectangular (plank-like) dunnage that will not roll should be chosen.

Figure 4 [André Brusselle]

In Figure 4, two things leap out at us: Firstly, the fact that here the far end of the belt has been threaded through so that this round-turn lashing could be pretensioned from both sides. And the second is the less than perfect level of cleanliness that we can observe very clearly not only in Figure 4 but also in Figure 2. Anyone who loads cargo of this weight with such „care and attention“ will not be getting a Christmas present from this load securing team.

Figures 1 and 4 also show the front ends of these lengths of steel. What cannot be seen is any attempt at load securing.

Because it is advent, we are going to have some fun and try to calculate what is involved in this special form of load securing. Let us assume that the load weighs 24,000 kg. This then has an approximate weight force of 24,000 daN on the surface beneath it. We assume that the square lumber below the cargo is bolted firmly to the base below it and, because of its extremely rough surface, we will allow the load itself a coefficient of friction of 0.45 μ. We further assume that each tie-down lashing (which we can perfectly well consider these painstaking round-turn lashings to be) contributes 750 daN on each side. This means that the load is „secured“ with 7,500 daN of pretensioning force. Unfortunately, these 7,500 daN are not applied vertically. Instead, at an angle of approximately 30°, no more than 50 % of this load securing force is acting vertically downwards. As a result, the pretensioning force acting vertically to increase the friction is reduced to 3,750 daN. If we now multiply this nevertheless considerable pretensioning force by 0.45, we come to 1,687.5 daN of securing force compared to the 8,400 that are actually needed. We are therefore missing 6,712.5 daN of securing force, even though we assumed unfeasibly high pretensioning forces and a very high coefficient of friction – in the same way as we ignored the fact that the dunnage consists of squared lumber.

Summary

How things can be improved:

- We would use dunnage with a rectangular cross-section.

- We would insert anti-slip material not just below the lumber but also above it, i.e. between the load and the dunnage.

- A total of four loop lashings should be used to secure the load at the side. When producing these loop lashings, edge protectors should again be used (as was correctly done here) at all the required locations to ensure that there can be no damage to the belts.

- 4,400 daN of securing force still has to be found in the direction of travel.

- To apply this remaining securing force, we recommend fixing two loop lashings around the front end of the load. To do this, we would saw off four blocks from the lumber that is simply pointing skywards at the edges, join these together using screws or nails, and place them on either side in front of the load. We would also use anti-slip mats below the lumber and, on this large crosspiece, we would use another block that is exactly the width of the three steel lengths taken together. Two loop lashings can now be passed around this block.

- It is essential to make sure that the loop lashings are of the same length. This can easily be achieved by applying the belts at an offset relative to one another (see diagrams / Figures 5 and 6):

- Because, as mentioned at the very start, the trailer was parked at a ferry port prior to being transported across the Baltic, we would consult the new CTU Code (www.deutsche-flagge.de/de/sicherheit/ladung/container) to find out the accelerations that the load must be able to withstand as Baltic freight.

On page 23 of the new CTU Code of Practice, we find the accelerations applicable to maritime freight. The Baltic forms part of sea area A, and an acceleration in the direction of travel of 0.3 g is specified, albeit for a reduced weight force of 50 %. Since the value in the direction of travel required for road transport is 0.8 g, the forward securing of the load on the trailer is sufficient.

However, it is possible for trailers to be loaded on ferries with their rear pointing forwards. To take account of this contingency, the load securing at the „rear“ (on the trailer) must meet the requirements for forward load securing on the ship.

The friction provided by our anti-slip mats achieves a securing force of 60 %. Because the vertical forces aboard ship may change due to the vessel’s pitching movements, we can only count on 50 % of the weight force. 50 % of the weight force corresponds to 12,000 daN. If we multiply this by our friction value of 60 % or 0.6 μ, we obtain 7,200 daN of securing force. This means that we are only just compliant with the requirements for sea area „A“.

On the Baltic, acceleration of 0.5 in the transverse direction must be allowed for. However, this can again be calculated using a weight force of 100 %, which means that our load securing arrangements are again sufficient for Baltic freight. - For freight transport on the North Sea, we again have a value of 0.3 g in the direction of transport but unfortunately only a weight force of 30 %. In this particular case, this means that the securing force in the forward direction is still sufficient but that we must ensure similar protection at the rear using belts. However, one belt is enough in this case because we are only missing 2,880 daN of securing force. Although we must allow for a sideways acceleration of 0.7, we may again base our calculations on a value of 100 % of the weight force of the load, which means that 60 % of the securing force is achieved through friction. Because our four loop lashings (two on each side) have secured approximately another 8,000 daN, this trailer can also cross the North Sea with a good conscience. The minor reservation was the need for additional securing force at the rear.

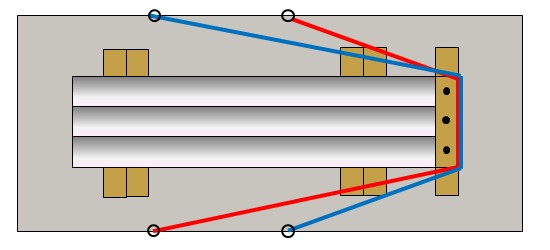

Top view (vehicle traveling to the right):

Figure 5 [GDV]

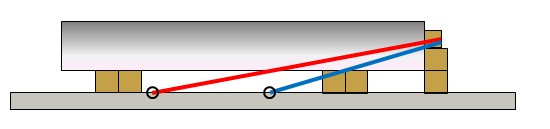

Side view (vehicle traveling to the right):

Figure 6 [GDV]

Conclusion

Ultimately, we have barely had to expend much more effort than the gentlemen who tensioned the silly loops so industriously. For the North Sea, we need seven belts and for the Baltic and road haulage, six. And all we have done is use the belts the way they were intended. Nothing more. But that’s what counts.

Back to beginning | Next Christmas special