| Photo of the month – February 2005 | [German version] |

Figure1 [Gilles Lancrey, Dakar, Senegal]

Pipes on their way from Lomé to Zinder

The pipes in Figure 1 which have made such a mess of the road and the truck that was carrying them were part of a large consignment of pipes that arrived by ship in Lomé (Togo) and were being transported by truck to Zinder (Niger).

Amazingly, driver survived the accident without injuries; you can see him seated on the pipes. We don’t have any details on exactly how the accident happened.

The pictures below suggest that the truck drivers must have been very courageous!

To transport the pipes, various trailers were fitted with specially designed steel frames. We know nothing about how these were secured. Assuming that the frames are securely attached to the trailer, we can assume that the load is secured laterally by means of a tight fit. Looking at Figures 2 and 3, we can see that the main focus when securing the load was on the longitudinal direction. The effects on the vehicle handling as a result of the high center of gravity of the load and the potential overloading are not taken into account here.

Figure 2 [Gilles Lancrey, Dakar, Senegal]

Figure 3 [Gilles Lancrey, Dakar, Senegal]

Each of these pipes weighs 400 kg. The pipes are combined to form load blocks each of which contains 36 pipes (14.4 tonnes). Each vehicle carries two of these blocks (28.8 tonnes). The pictures show that the load is secured against shifting forwards simply by the friction force of the load and frictional securing afforded by two or three tie-down lashings per block. You can also observe gaps between the blocks and the end walls which are utterly under-dimensioned and above which the pipes protrude.

A simple calculation to determine the number of required securing elements for the method used (tie-down) results in 24 belts per load block:

| The inertia force to be secured in the longitudinal direction is 0.8 g* of the load weight (i.e. 80% of the weight of the load). The required securing force to the front for each block is thus:

14 400 kg x 0.8 g = 11 520 daN * [g = 9.81 m/s2–> 10.0 m/s2] |

|

| Securing force created by friction, assuming a frictional coefficient of µ = 0.4 between the pipe and the wood: 14 400 kg x 0.4 g = 5 760 daN |

|

| Shortfall in securing force: 5 760 daN | |

| Securing force of one tie-down lashing, assuming pretensioning in straight line of 300 daN for each end of the belt, thus, 2 x 300 daN = 600 daN The securing effect of a single tie-down is thus: Securing force x friction coefficient = 600 daN x 0.4 = 240 daN |

|

| Number of belts required for the tie-down securing: Securing force not yet provided divided by the securing effect of each belt = 5 760 daN / 240 daN = 24 lashing belts |

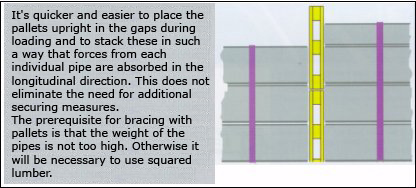

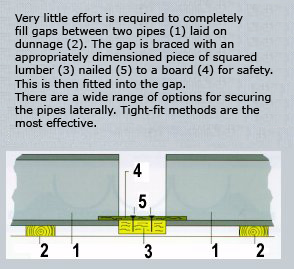

Gaps between the blocks could be filled in as shown in Figures 4 and 5 below.

Figure 4

Figure 5

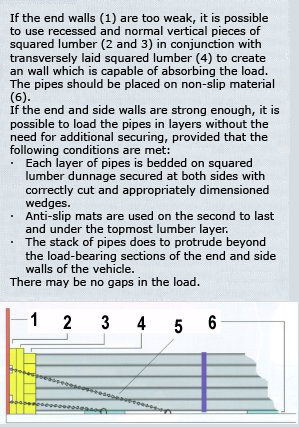

Figure 6 shows a method of securing which can be used when vehicles have no end walls or insufficiently sturdy end walls.

Figure 6

Just as an aside:

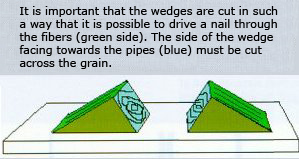

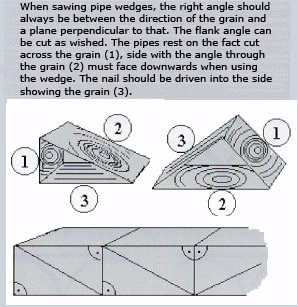

The arrangement of the wedges could have been be improved (see Figures 7 and 8):

Figure 7

Figure 8

The Cargo Securing Manual contains additional information regarding the secure transportation of pipes.

[bvd]

Back to beginning