| Photo of the month – January 2026 |

[German version] |

The Four Seasons

1. Winter festivals

“Now someone else is going to be punished just because it’s winter,” groaned the senior manager in his broad Berlin accent. He had hurried out to meet his driver who was having trouble with the police.

Completely unjustifiably, they were both agreed on that as they stood there shaking their heads.

Figure 1 [F. Schmidt]

Just because a container for a skip truck, brim full with building rubble and, according to the driver’s estimate, weighing some 10 tonnes, had been loaded onto the snowbound vehicle without any suggestion of a tight fit.

There was also no tight fit to the side, even though the planks visible in the foreground could have been used to fill this gap.

Figure 2 [F. Schmidt]

Friction? Metal on fine-grained, polished metal on a layer of snow, itself predisposed to turn into ice as it was compressed under the weight.

No friction – no load restraints. What was this container supposed to do?! The two of them just shook their heads.

Figure 3 [F. Schmidt]

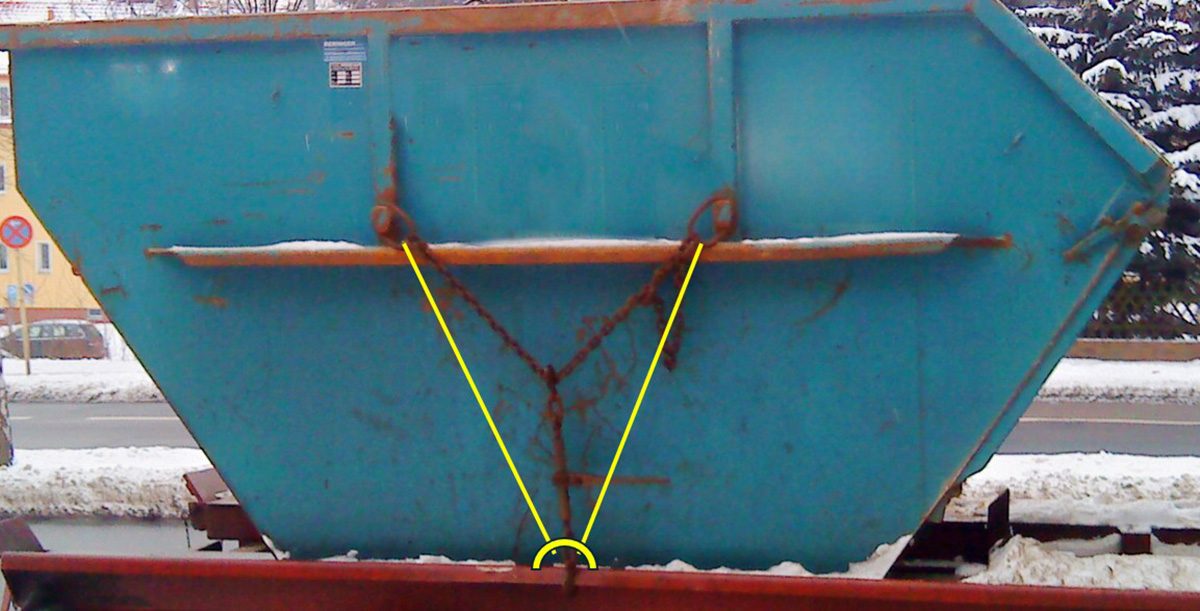

What about, what about … the skip chain, the two gentlemen seemed almost amused. But even the carrying chains were slack and sagging loosely in the air. Many body manufacturers allow these carrying chains to be drawn taut and used to secure the load to the rear.

The trailer offered a similar picture. Here, a lashing chain had been attached in a “Y”-shape. As a result, it could have acted as a genuine tie-down lashing, if it had not been for the fact that the lashing hook was causing the bottommost chain link to bend considerably. This is exactly how not to do things! A tie-down lashing amplifies the existing fiction, and as we know, there wasn't much of that to go round!

Figure 4 [F. Schmidt]

An appropriately dimensioned lashing configuration with two lashings on each side, as depicted by way of an example here, could have solved this problem:

Figure 4a [F. Schmidt]

Do we have to add that a suitable lashing point must be present for this to be possible? The next photo clearly shows what happens to the external frame when a hook is attached to a point that has not been designed for this.

Figure 4b [F. Schmidt]

The external frame has already been significantly bent out of shape due to the force exerted by the lashing equipment.

For the driver, who in this case was also the loader, the upshot of all this was a fine plus administrative costs and the loss of a point from his driving license. The senior manager who had hurried to his aid was responsible for the deployment of the vehicle and was faced with a €270 fine plus administrative costs and the loss of a point.

A consequence that wiped the smile off their faces….

Could all this have been avoided? Here are some ideas based on how other people go about transporting skips.

First of all, we must take care of the tight fit. Vehicle maintenance and departure checks must include making sure that it is viable to use adjustable blocking mechanisms!

Figure 5 [F. Schmidt]

There’s not a lot that can be done about the friction. Smooth metal is rubbing against smooth metal. With nothing but fragments of crushed material between them. These act like tiny rollers – and correspondingly little friction is available to secure the load.

This is how one market consultant used blocking mechanisms and took account of friction to secure a container in the direction of travel and to the side. This is an easy task for the driver to accomplish, assuming that the vehicle has been maintained in a proper condition – which, it should be mentioned, is the owner's responsibility and comprises much more than just the annual inspection and safety inspection. If this is not the case, then it is high time for the owner to act!

What remains is the load securing to the rear, which should not be neglected under any circumstances.

This task is often left up to the tough and powerful-looking tail hook – as can be seen in the following photo, which depicts another skip truck.

Figure 6 [F. Schmidt]

And it then becomes very easy to forget about the gap, given that the tail hook looks so big and strong. Figure 7 shows exactly how far this container was able to slide before bringing its entire bulk to bear on the hook.

Figure 7 [F. Schmidt]

The measurement made by the police revealed a considerable free space of approximately 30 cm.

However, this hook is not suitable for securing loads even when a tight fit is present, unless of course the manufacturer has explicitly described and confirmed the hook’s suitability for such purposes. Our two gentlemen knew nothing about this.

So how can the skip be secured against the direction of travel?

There are several possibilities.

Securing using the carrying chains:

Figure 8 [Dr. Uwe Krause]

Extend the lifting arms until the backwards-pointing carrying chain is taut. When doing this, it is necessary to bear a number of things in mind.

The chain must not be tensioned, i.e. it must not be pulled excessively tight. This might lift the container slightly, making everything too unstable.

The manufacturer must confirm, as many do, that the system is suitable for this purpose. This information can be found in the instruction manual. A certificate from a testing organization may also testify to suitability.

Figure 9 [F. Schmidt]

Figure 9 impressively illustrates the possible distance of travel before a sagging chain becomes taut. However, a moving container introduces a completely different force into the rapidly tightening chains than a stationary container that is simply being held in place and prevented from slipping

In practice, when the vehicle is moving, drivers are alerted by a warning signal in the cab, and if the signal is acoustic in nature, this can prove to be quite annoying …

Last but not least, it is essential to pay attention to the vehicle’s height. What use is a secured skip if you can no longer get under a bridge….

Inclined lashing:

The vast majority of vehicles with superstructures designed for skip transport have lashing points.

Figure 10 [F. Schmidt]

In most cases, these are lashing points with a strength of 5,000 daN, corresponding to approximately 5 tonnes. Have you ever wondered why 5-tonne lashing points are installed in these vehicles, while “normal” 40-tonne trucks only have 2-tonne lashing points? The answer is simple: Because this force is needed. The friction is so (incalculably) poor that it should be ignored when using this securing method.

Figure 11 [F. Schmidt]

In practice, attaching the lashing equipment to the container is particularly challenging. But solutions are also available here:

Attachment by means of a lashing point at a rhombic link

Figure 12 [F. Schmidt]

In this case, the lashing equipment is attached directly to the corresponding lashing eye on the connecting link at the carrying chain and attachment point.

If no such rhombic link is present, then it is also both possible and effective to connect a shortening hook to the carrying chain close to the attachment point.

Figure 13 [F. Schmidt]

In this case, it is simply necessary to make sure that the section of the carrying chain leading to the lifting arm is slack. The force must be transmitted directly from the lashing point to the attachment point, and the slack chain section must not be subjected to load.

One of our contemporaries must have been feeling a little adventurous. He connected a carrying chain and lashing equipment via an intermediate link.

Figure 14 [Frank Schmidt]

This is admittedly not the optimum solution, but it does show that the loader was aware of the problem and that he thought about possible ways to overcome it. Since all the load values were as they should be, this load was waved on untroubled by the police.

Another possibility is to use special connecting elements that can be attached directly to the container’s suspension points.

There are two possibilities:

Figure 15 [F. Schmidt]

Figure 15a [F. Schmidt]

Figure 16 [F. Schmidt]

In the example shown in Figure 16, wire rope eyes were used to good effect. The load values made this approach possible. Greatly accelerated wear is the only concern we should mention here. This is because the transmission of the force at an intermediate link that has no cable eye reinforcement can rapidly lead to damage when the loads are high enough.

Conclusion: Exchangeable containers also have to be secured if they are not fastened to the vehicle itself.

Responsible vehicle operators/users will find a whole host of other container securing methods available on the market, for example in the form of hydraulic container clamping using locking feet, engagement of the securing gear in the rocker bearing, retention of the carrying chains using hydraulic presses, etc., etc., etc..

2. We’re all going on a summer holiday, let’s forget about what we have to do….It seems very likely that the driver responsible for this load had some such laid-back melody going through his head. However, this recently photographed transport operation clearly shows that container securing is important whatever the weather.

Figure 17 [F. Schmidt]

It was not only the container itself that stood almost totally unsecured on the vehicle!

The load present in the container was also just about ready to scatter itself all over the road.

Given that there were no blocking mechanisms to keep the load in place and no nets, tarpaulins or lashing equipment present on board, another vehicle had to be summoned to the site and the load transferred to it.

And a fine and the loss of a license point made the sun shine a little less brightly.

3. Autumn impressions…are shown in the next set of photos. Yes, this load really was to be seen on our roads! We really don’t want to comment. Just to say that a cold autumn chill ran down our spines…..

Figures 18- 21 [F. Schmidt]

We can’t think of any way to secure a load like this any better, except: Do almost everything differently!

4. Spring awakeningSpring is known to be the season when everything awakens and bursts into life. In this example, that doesn’t include responsibility.

Figure 22 [F. Schmidt]

A police patrol following this vehicle had noticed the imposing mound of rubble and the obvious risk of the vehicle shedding its load.

Figure 23 [F. Schmidt]

The heaped up rubble was a sign that the load might well exceed the permitted total weight. How could the driver have recognized this?

The “overload indicator handed down through the ages”.

As we last showed very clearly in this column back in June 2016, this simple indicator can be used to identify excessively heavy loads.

Figure 24 [F. Schmidt]

If more than three tread blocks are in contact with the road surface, then the vehicle may be overloaded.

We wish you a Happy and Healthy New Year: Your Load Securing Team

Back to beginning