| Photo of the month – December 2025 |

[German version] |

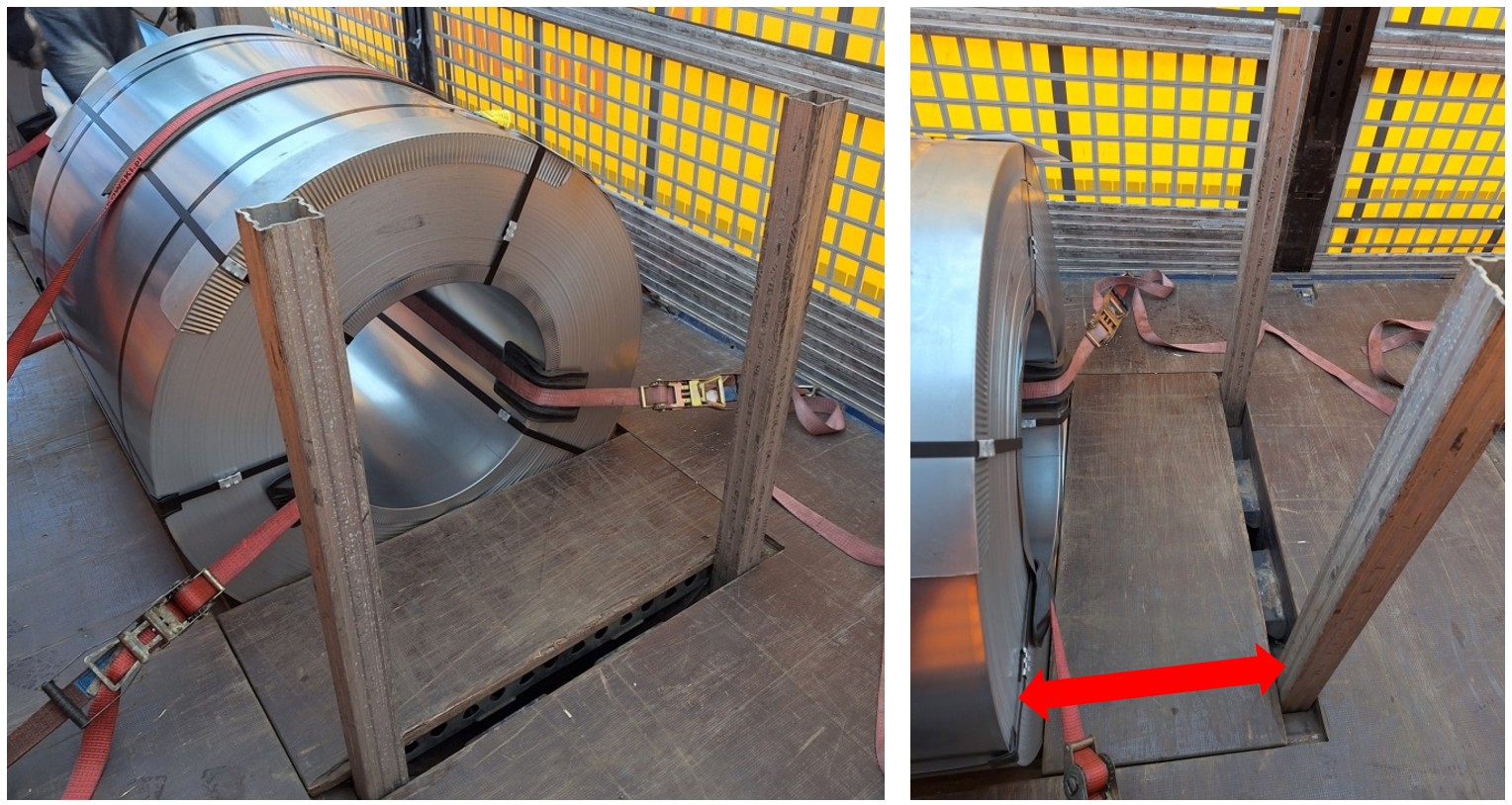

STANCHIONS – Are they just a sham?

Do they actually do what we expect them to?

… so many open questions

… looking for answers

… unfortunately, too often in vain

… a critical analysis

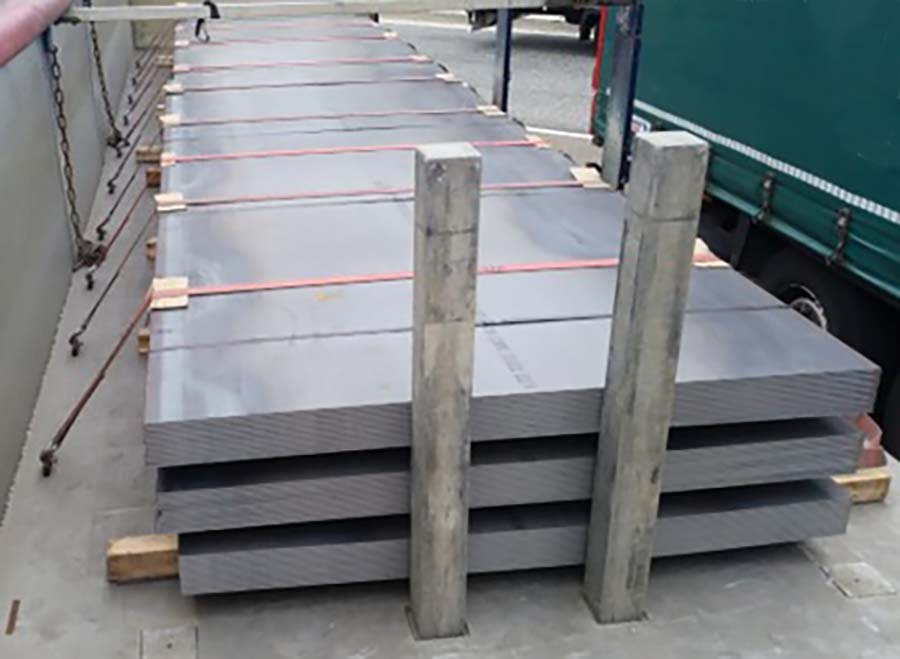

Figure 1 [Raymond Lausberg]

Stanchions are often used to transport steel, among other things. The hope is that they will block the load to the front, where the greatest forces arise. When transporting timber, they are used to block the load to the sides.

They turn up in all sorts of shapes: square, rectangular, round and even telescoping.

Figures 2- 5 [Raymond Lausberg]

They are usually made from either steel or aluminum.

Figures 6- 7 [Raymond Lausberg]

Both certified and non-certified stanchions are available on the market. What is more, they can be either reinforced or non-reinforced.

However, in this article, we would like to look at them in a little more detail. A vague, casual assertion like “that will hold” won’t get us very far in a serious calculation.

The sentences above are already enough to get us asking a number of as yet unanswered questions.

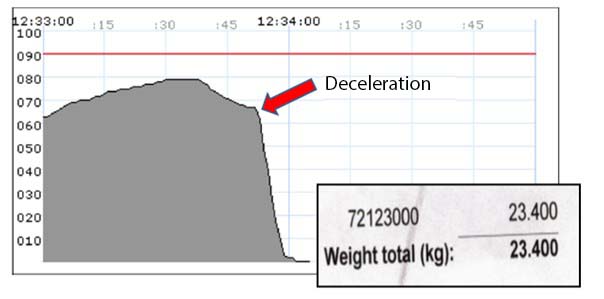

Figure 8 [Raymond Lausberg]

Extracts from manufacturer’s specifications

Aluminum stanchions broken after just a slight deceleration.

Figure 9 [Raymond Lausberg]

Figure 10 [Raymond Lausberg]

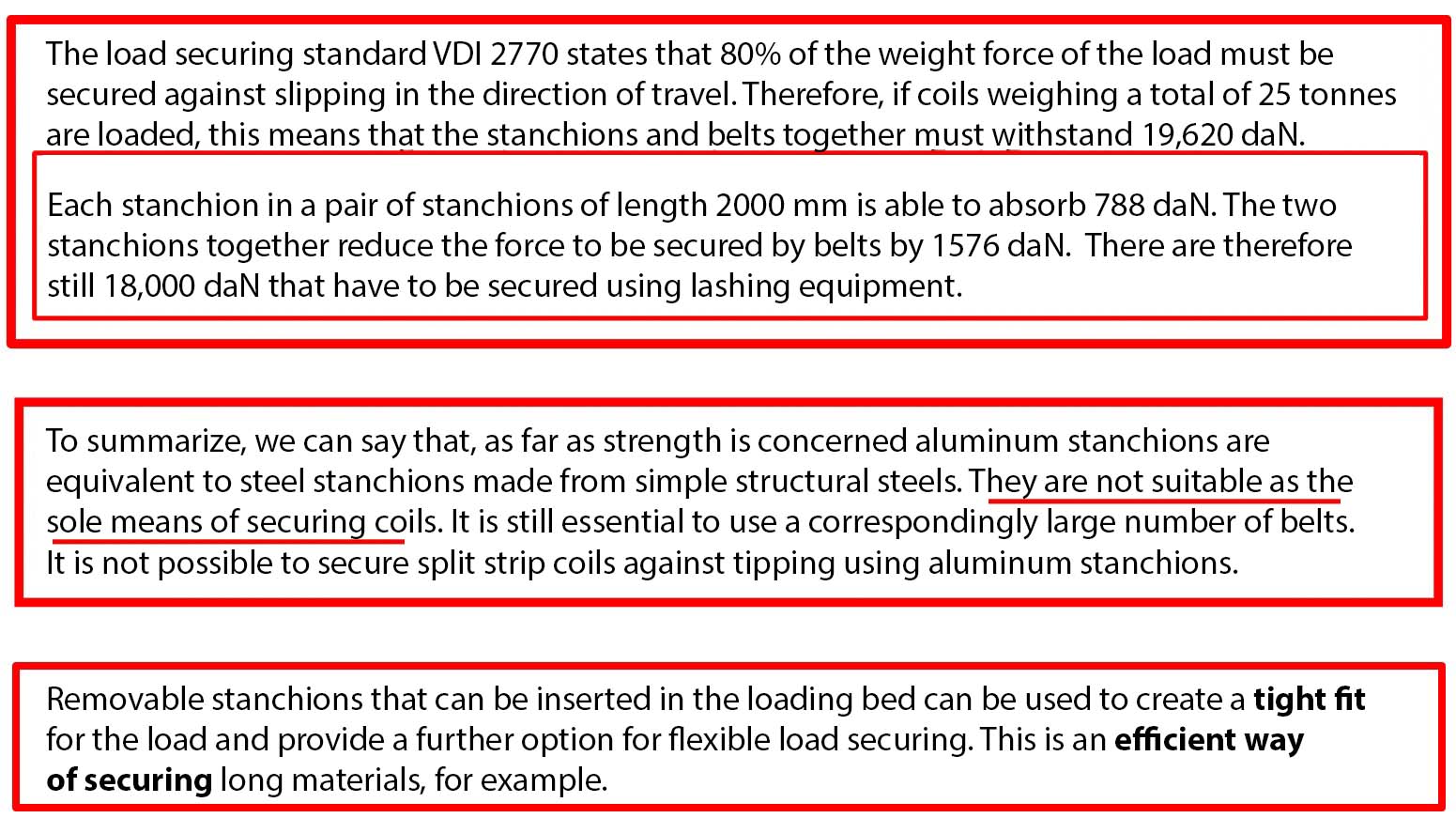

Blocking capacities (BC)

Searching for the hoped-for information about the load values of the stanchions available on the market is a very laborious and unrewarding task.

An example can be found below:

Since the provided information was mostly unsatisfactory, misleading or even completely absent, we have deliberately decided not to name any of the manufacturers here.

As expected, the load values are naturally highest at the level of the stanchion pocket.

However, if forces are introduced higher up, then these values fall rapidly.

Generally speaking, we can say that at a height of 1 m, these values (BC) are less than 1,000 daN for the products of the majority of manufacturers and therefore fall well short of expectations.

Suggestions for improvements:

Clearly, a few manufacturers have now recognized that it is vital to improve their stanchions and their poor load values.

This makes the stanchion reinforcements available on the market all the more welcome.

They can be found in a number of variants. Sometimes they are reinforced with cross-struts, while sometimes is also possible to attach one or more head loops.

Figure 11 [Raymond Lausberg]

An example from practical use

Here, a recess cover is misused to provide a tight fit. The force that a cover like this can withstand is completely unknown.

Figures 12- 13 [Raymond Lausberg]

Conclusion

It is necessary to be extremely cautious when using stanchions to block loads.

In particular when transporting slit strip coils, the use of stanchions that have not been additionally reinforced is to be vigorously discouraged.

What is more, such coils should be bundled together to minimize the risk of tipping.

The use of stanchion reinforcements (cross-strut or head loop) is recommended.

Back to beginning