| Photo of the Month – April 2024 |

[German version] |

22.1 tonnes is too much to trust to luck!

An excavator weighing 22,100 kg was being carried on a five-axle lowloader. The load was too wide and the total weight approximately 6 tonnes too great. This means that a special permit and express authorization would have been needed for the operation. In purely technical terms, the articulated truck was suitable for transporting this load.

In this article, we will concentrate on the load and how it was secured.

Figure 1 [TIS-GDV]

Figure 2 [TIS-GDV]

Figure 2 shows that the load appears to be correctly distributed, and that is an obvious plus.

Figure 3 [TIS-GDV]

In Figure 3, we get closer to the crux of the matter: the direct lashing that crosses over itself here. Because of this crossover, this type of lashing is very often referred to as a diagonal lashing. However, it is in fact nothing other than a direct lashing and we will evaluate it as such. While we are about it, we ought to clear up a few misconceptions and point out that, in general terms, it is all right right for chains that cross over like this to touch. Such crossovers themselves are also completely harmless even though not always necessarily useful – a point which we will return to below.

In Figure 3, we get a good insight into the friction. We have pointed out very frequently that it is always difficult to get construction vehicles onto a trailer with the tracks or tires clean. It would therefore be an advantage if the load securing equipment were chosen in such a way that no friction was needed to restrain the load.

In this case, the loading surface is relatively clean. The rubber track is only slightly soiled with earth but still enough to impair the friction. We will err on the safe side and assume friction of μ = 0.3.

Figure 4 [TIS-GDV]

To take a closer look at the load securing measures, let us move on to Figure 4, which shows the excavator from behind. When we say “behind”, we are referring to the direction of view, which is looking forwards. The two chains must apply a securing force of 11,050 daN. Given that each of these chains has a lashing capacity (LC) of 6,300 daN, this will be a challenge because the longitudinal components of the chains will need to be extremely good – and they clearly in no way meet this requirement.

Load securing equipment is often crossed over itself for the simple reason that the load does not possess any usable load securing points in easily accessible positions. This is a clear cause for criticism and something that the manufacturers should consider. To check the load securing, we make use of our “cookbook”.

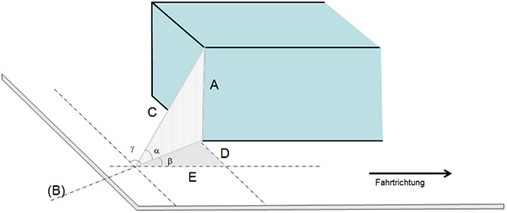

Diagram 1 [TIS- GDV]

This is simpler and more practical to use than any other method of checking the load securing. What do we have to do? We measure distances and express them as ratios to one another. These very ratios are described by angle functions which, however, we do not need to use because we work directly with distances and the corresponding effective restraining directions. Using a tape measure, we obtained the following distances

- C = 3.00m – Effective length of the load securing equipment

- E = 0.90m – Longitudinal component

- D = 2.25m – Lateral component

- A = 0.0m – Vertical distance between the load securing point on the load and the point at which the force is transmitted to the loading surface.

To determine the securing force in the longitudinal direction, we take the longitudinal component (E) and divide it by the effective length of the load securing equipment, i.e. 0.90 : 3.00 = 0.3, which means that only 30% of the LC of the items of load securing equipment is acting in the longitudinal direction, i.e. 6,300 daN x 0.3 = 1.890 daN. Because both items of load securing equipment have the same length ratios, we can simply double the determined value. Consequently, this excavator is secured with 3,780 daN plus frictionyou in the longitudinal direction. What is actually needed is 11,050 daN, meaning that there is a shortfall of 7,270 daN.

To determine the securing force in the transverse direction, we take the lateral component (D) and divide it by the effective length of the load securing equipment (C), i.e. 2.25 : 3.0= 0.75. The excavator is therefore secured to the side with 75% of the LC of the load securing equipment. This corresponds to: 6,300 daN x 0.75 = 4,725 daN. Since the chains at the front have a similar geometry, we assume, for the sake of simplicity, that they also have similar securing values. The excavator is therefore secured with 9,450 daN to the side. However, assuming friction of μ = 0.3, we actually need only 4,420 daN. So we have far more than we really need and there’s nothing wrong with that … but it does point to a considerable imbalance.

Like any other securing measure, this direct lashing also has a vertical component. In extreme circumstances (emergency braking), the excavator would move forwards a little in the load securing equipment and tension it up to its LC. This maximum permissible tensioning then also acts in the vertical direction, thereby increasing the friction. To determine this value, we take the vertical securing component and divide it by the effective length of the load securing equipment. 0.6 : 3.0 = 0.2. This means that 20% of the LC is acting in the vertical direction and therefore making the excavator artificially heavier.

6,300 daN x 20% = 1,260 daN. Because two of these items of load securing equipment our tensioned simultaneously, we obtain an overall vertical component of 2,520 daN. This securing effect of this vertical force is modulated by the friction of 30%. 2,520 x 0.3 = 756 daN. The advantage of this security method is that it acts in all directions. However, it by no means makes up for the shortfall in load securing in the longitudinal direction.

The chains would have to be moved backwards until the ratio of the longitudinal component to the effective length of the load securing equipment is equal to 0.88. If there were two load securing points in the middle of the excavator, then the chains would no longer have to cross over and their longitudinal component would be greatly improved. We do not know whether the vehicle geometry provided the corresponding load securing points at the required positions. One solution would be stronger chains and, of course, the corresponding load securing points on the vehicle and, of course, also on the excavator. With an LC of 10,000 daN, the driver would not end up having to be so parsimonious about length ratios.

Follow the link below to find a highly detailed presentation of the “cookbook” and its advantages.

youhttps://www.tis-gdv.de/tis/ls/praxis/diagonalzurren/inhalt1-htm

Your load securing columnists as always wish you a safe and secure journey!

Back to beginning